Dr Brian Adjetey Boye, a Senior Associate Director of Tunnelling and Geo-Digital with Jacobs, presented a paper entitled ‘Kalvebod Tunnel and Shaft Induced Settlement Automation Using Autodesk Dynamo Tool and Civil 3D’ at WTC 2022, in Copenhagen. The paper was co-authored by S. Botusharova, M. A. Jørgensen, and L. Erichsen. An abridged version is published here with the authors permission

INTRODUCTION

The risks and impacts due to ground movement associated with tunnelling works in urbanised areas need to be assessed in the early stages of tunnelling projects (including route optioneering) as well as during the design and construction/commissioning of the project.

This article describes the use of a novel method to undertake the estimation of ground movement and building damage assessment. The approach renders the often tedious and time-consuming spreadsheet calculations into an automated workflow that is efficient, rapid, reliable and allows the damage assessment of 1000+ buildings and utilities.

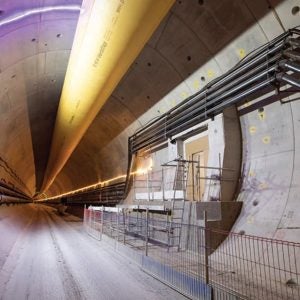

The developed tool was applied for the automatic generation of ground movement data related to the construction of the 1.25km-long Kalvebod Brygge Skybrudstunnel Drainage Tunnel with three shafts, in Copenhagen (see Figure 1). The tool is known as TunDRA (i.e., Tunnel Damage Risk Assessments). It based on Autodesk Dynamo and Civil 3D, which have been used in the past for highway linear schemes, but this application is novel for tunnel settlements.

The ground movements are predicted based on empirical methods and can be estimated for any location in three-dimensional (3D) space. The tool also allows for the identification of affected buildings, particularly those with protected status and at the early stages of projects, such as route selection. The tool generates Computer Aided Design (CAD) ready contour lines in Civil 3D while pulling in alignment and ground surface information efficiently and therefore avoiding the need for manual data entry.

This innovative approach results in an increased output quality and consistency as well as time and cost savings. The tool has been applied on more than 10 projects, including a project in Canada as described by Boye et al (2021). Similar tools have also been developed for other aspects of tunnel design including automatic drawing production.

PROJECT OVERVIEW

Jacobs is part of the group of consultants on this project with NIRAS being the lead consultant. The client is HOFOR (Greater Copenhagen Utility) and Fredriskberg Forsyning.

The need for this flood alleviation project was brought about by flooding events in the Danish capital. Over several years, HOFOR will be constructing a number of cloudburst storage and flow diversion tunnels to help protect the city against flooding. One of the tunnel projects is the Kalvebod Brygge Skybrudstunnel. It will convey runoff collected from existing nearby sewers to a large pumping station for discharge into Copenhagen harbour.

The Kalvebod Brygge Skybrudstunnel is composed of two sections (see Figures 1 & 2):

- The section between Skt Jørgens Lake (JØR shaft) and Søner Blvd (SB) shaft, is 2m i.d. and 725m long. The depth of tunnel below ground along this section is approximately 12m to 17m (depth to crown).

- The section between SB shaft and Kalv pumping station, near Copenhagen harbour, is 3m i.d. and 540m long. Depth of tunnel in this section is approximately 11m to 12m (depth to crown).

The Kalv pumping station was designed by Jacobs. SB and JØR shafts were designed in parallel by NIRAS.

Based on information from ground investigations, the tunnel face is mostly located in glacially disturbed Upper Copenhagen Limestone (UCL). In the area of the proposed tunnel and shafts, UCL is typically overlain by Greensand (sand and limestone); Lower/middle meltwater (sand); Lower clay; Upper clay; and, fill/post glacial deposits.

This project is highly complex due to its ambitious size and planned pumping capacities.

But the Kalvebod Tunnel project also traverses a highly urbanised area with many buildings of historic and cultural significance as well as important existing infrastructure, such as a busy railway line and a metro line.

Due to the location of the tunnel and the existing buildings and infrastructure above, the project required establishing a building damage assessment procedure. This work included pre-assessment of 40No. buildings above the tunnel centreline, most of which have been classed as heritage buildings for conservation.

TYPICAL METHODS OF SETTLEMENT AND IMPACT ANALYSIS

Typical methods to determine magnitudes of tunnel settlement and building impact analysis involve data management using Excel spreadsheets and other commercially available software tools. These methods often have only limited integration with CAD software and also are limited in their data handling capacity in dealing with large terrains with thousands of buildings.

Often numerous spreadsheets are required and manually plotting the settlement contour lines in a CAD package. Furthermore, there is often a need to combine settlements from multiple underground structures (tunnels, shafts, cut-and-cover structures, and cross passages) which can be very tedious and time consuming.

OVERVIEW OF CAD AUTOMATION

CAD was initially developed with the aim to use computers in a way that could mimic the traditional manual drafting process. The focus has been to use CAD to produce printed 2D drawings on paper as opposed to generating digital models in 3D for design analysis. However, recently there has been a shift in emphasis, with tools like Autodesk Civil 3D and Bentley OpenRoads, which have been developed to also represent model entities like alignments, road corridors, topographic points, surfaces, and pipe networks. These software suites are integrated with packages and advanced entities to support the Building Information Modelling (BIM) approach for civil engineering infrastructure projects.

As highlighted by Kontothanasis et al (2019), one of the key changes that BIM brings to infrastructure projects is interoperability, that is the integrated model which combines all desired disciplines, designconstruction stages and input from all parties in a Common Data Environment (CDE). To facilitate this kind of integration and CDE, Autodesk have provided a plugin known as Dynamo within its Civil 3D software, enabling the use of visual programming to pull-in data from other software/design tools and create workflows to automate the design process.

Figure 3 shows a screenshot of Civil 3D with the Dynamo plugin on the top/right corner.

DEVELOPMENT OF WORKFLOW

The development of the successful solution relied on the co-operation and collaboration of several parties. Liaison with Autodesk was important in providing the training and guidance on the functionality of Dynamo. The platform is open source, which means that the code is open for everyone to see. Dynamo is built on a community that contributes to making it better (Autodesk, 2020).

Civil 3D and Dynamo were chosen for the automation needed for the data-intensive settlement analysis because they integrate with existing digitised information, such as: the tunnel alignment information; ground surface information from LiDAR surveys; and, building outlines in CAD format.

Using available information with little or no modification is important to ensure that no errors are within the workflow or automation due to preprocessing. Other advantages of Dynamo include:

- It allows the use of visual programming to construct logic routines, which makes it easier for users without an extensive programming experience to use and generate automatic workflows.

- CAD geometry can be created parametrically and pushed into Civil 3D drawings, and this offers time savings when compared to manual creation of geometry in a drafting package.

- It allows interfaces with multiple software (AutoCAD, Excel, MathCAD, and third party tools) and can be integrated with python and C# programming to allow advanced users to develop more powerful bespoke tools.

The workflow for the settlement and impact analysis was developed by pulling-in information mainly from Civil 3D drawings with some additional settlement parameters from Excel as shown in Figure 4.

The main inputs to the settlement analysis included the tunnel alignment, ground surface topography and the settlement trough parameters for each tunnel or shaft in Excel Format as shown in Figure 4. The different inputs were combined in Dynamo. A screenshot of the Dynamo graph is shown in Figure 5. This visual programming interface creates connections that define the flow of data and information. The main node ‘calculate settlement’ in the middle of the graph links to the C# scripts that carry out the numerical calculations to determine the settlements.

COMPUTATION OF SETTLEMENTS

To enable settlements from multiple tunnels or structures to be combined, calculations were carried out on a grid. Settlement values at the same points on the grid could then be easily added together. Empirical formulae by Attewell and Woodman (1982) were used to calculate the tunnel settlement distribution whilst the formulae by New and Bowers (1994) were used for shaft settlements. It was important to include input validation in the tool so that inappropriate or missing inputs were immediately highlighted to the user. A unit testing software program was implemented to detect errors/bugs and deficiencies at early stages of functional implementation and also to ensure that these would not be introduced during version updates.

KALVEBOD PROJECT RESULTS

A bespoke solution was developed for undertaking settlement and building damage assessment calculations for the Kalvebod Brygge Skybrudstunnel project, considering the influence of the tunnel’s three shafts and any auxiliary (temporary) structures associated with their construction on the ground movements in 3D space.

The settlements for each excavation type were calculated simultaneously and combined to obtain the cumulative ground movement, which was then used in the impact assessment for the buildings.

Calculated cumulative settlements were shown on a contour map, overlaid on the tunnel alignment and cadastral maps (see Figures 6 and 7). Calculations were undertaken on a 0.2m grid to create a detailed map of the movement and their rate of change nearing the excavation structures.

For this project, the building damage assessment was carried out in a semi-automated process. However, the tool has since been further developed to a fully automatic process where closed polylines in the drawing representing the building footprints are analysed.

The semi-automatic process involved adding ‘Query’ lines (in the form of closed polylines in Civil 3D) for the geometry of the 40No buildings in the vicinity of Kalvebod tunnels/ shafts/ supporting structures. Those were drawn along the façade or side of the building nearest to the tunnel. These lines were then retrieved by the Dynamo program during analysis and 3D ground movements were interpolated at a depth estimated to coincide with building foundation depths (usually 1.5m – 2m deep). The results of the 3D ground movements were then used in the damage assessments.

DISCUSSION

Current methods for the analysis of ground movements and building damage assessments rely heavily on Excel spreadsheet calculations which can be tedious, timeconsuming, and prone to errors, especially for large topographies.

Automation of the calculations in the analysis brings the ability to source data from 3D models (existing topography and existing infrastructure information) as well as proposed design information (tunnel alignments and other excavation structures), and with some user inputs (such as geometry, volume loss parameters) to produce estimated ground movements within a matter of minutes.

When using established semi-manual methods of calculations, iterations to the design or input data (e.g., change of tunnel diameter or further ground investigation) require the same amount of effort and time to re-run again, as if from scratch. This is where automation plays a huge role in allowing iterations to be made seamlessly and at a fraction of the time it takes for manual calculations.

As an example, the work on the Kalvebod project initially only involved ground settlement and building damage assessments for the tunnels only. The client then requested that the calculations be revised to include the impacts of the shafts as well as any supporting/ auxiliary structures to be included. The additional structures were added to the inputs and the automated tool was then re-run in a significantly short period of time.

This approach allowed for a major revision of the scope of work to be handled quickly and efficiently with minimal impact on the overall project programme.

The use of automation also allowed the quick identification of which buildings had a category of damage above ‘negligible’ and further consideration to be given to them. This work included detailed analysis needing to be undertaken, as well as visual inspections, monitoring equipment installation and any mitigation measures necessary to adopt.

The success of utilising automation for ground settlement and building damage assessment on the Kalvebod project was manifested in the reduced need for time-consuming, repetitive calculations, ability to source and process a very large amount of data and to produce consistent outputs. A significant reduction in person-hours for such tasks is realised, allowing engineers to focus on more complex problems.

The ability to customise the output data in both spreadsheet as well as visual format was also beneficial for both use in further calculations or for presentation to the client and other stakeholders.

CONCLUSIONS

Automation of design calculations in civil engineering is becoming more prevalent due to its immediate benefits to design engineers – such as reduced need to undertake repetitive calculations, ease of checking, and ability to interpolate large amounts of data.

Furthermore, automation as well as the use of software such as Civil 3D and Bentley OpenRoads allows the better co-ordination between various disciplines working on infrastructure projects, which ultimately contributes to the fulfilment of BIM objectives and the digital transformation of the engineering and construction industry.

The application that has been described in this article pertains to the final stages of the design of a tunnelling project.

However, this tool also has been adopted in the preliminary stages of design on other projects, bringing great benefits, such as the ability to assess the impacts of the tunnel on existing infrastructure and to take this into account at the optioneering stage.

Construction of the Kalvebod project started in 2022. The SB and JØR shafts are excavated and base slabs cast.

OUTLOOK

Integration of workflows with different software packages is becoming ever more important. Integration with MathCAD to present formulae adopted to the user is being added to the tool. Also, ArcGIS support is being added to enhance the user experience.

It is also important to encourage client and stakeholders to keep data about their assets in a digital format.