After 15 months, the micro TBM (MTBM) that was tangled in tensioned steel tie-back wires, and so stuck on a section of Toronto’s Basement Flooding Protection Program, was finally retrieved.

The MTBM had begun boring in March 2022 to install a 3ft-diameter (900mm) storm sewer. But a few months later, in June, became ensnared in the tie-backs that had been placed during prior construction works as part of brace shoring for two mid-rise developments in the area.

Encountering the tensioned wires was entirely unexpected. The City of Toronto said details of the tiebacks were did not appear during prior research for the project, such as deep foundation shoring on as-built drawings for the mid-rise developments.

The section of the Basement Flooding Protection Program involved in the trenchless tunneling is Phase 4 Contract, on Old Mill Drive. It involved a 308ydlong (282m) stretch of new sewer tunnel between maintenance holes OD5 and OD8.

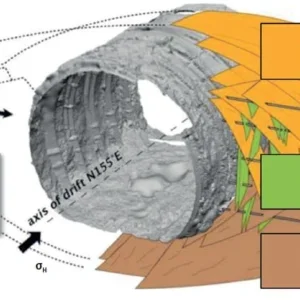

To get over the problem, the City – as the local authority and project owner – issued an emergency contract, to Clearwater Construction Ltd, aiming to retrieve the MTBM reasonably quickly. It also wanted to avoid wider difficulties for local infrastructure from excessive groundwater and poor soil conditions around the trapped machine near the unmapped foundations tie-backs. Risks were of concern such as creating difficulties for the integrity of the roadway, the nearby subway tunnel and surrounding infrastructure due ground movement. A sinkhole had appeared in the work zone.

The recovery works would start with an examination of the trap zone, then destressing and removing steel tiebacks, removing the MTBM, and undertaking jet and compaction grouting to stabilize the ground. It was hoped the works would be able to be executed quickly. However, they proved more of a challenge.

The 3ft 11in.-diameter (1.2m), 16ft 4 in.-long (5m) MTBM was working at a depth of over 19ft to 59ft (6m-18m) to avoid conflict with the nearby Old Mill TTC Subway tunnel. It had completed the majority of its drive when it hit the tiebacks.

The City of Toronto decided to retrieve the machine because leaving it in the ground would have required the sewer to be completely redesigned and reconstructed which would have been cost-prohibitive and extended the project’s duration.

A spokesperson for the City’s Engineering and Construction Services division said that the retrieval was a complex operation, requiring more time and cost than initially anticipated.

The spokesperson said: “During initial retrieval efforts, a significant amount of groundwater entered the tunnel, which needed to be removed and the ground needed to be stabilized in order to safely continue work and remove the machine. The ground stabilization work was more complex than originally anticipated. However, the area always remained safe.”

The first purchase order for the retrieval was for Can$8.99 million (US$6.6 million). As efforts to retrieve the machine progressed, the City amended the purchase order for an additional allocation of up to Can$16 million (US$11.8 million).

“This represents the upper limit of the cost estimate, and it’s possible that the cost won’t require the entire amount. The final costs and actual payments will be based on substantiated and certified invoices.”

With the MTBM removed, work then restarted on the new sewer line to be built on the Old Mill Drive section of the project, and completion is expected toward the end of the year.