As a tunnel surveyor with Eiffage, a French civil engineering construction company, Christophe Poloni knows a thing or two about uncertainty.

“I’ve worked on many underground projects and the one thing they have all had in common is the uncertainty of not knowing what we would find,” says Poloni. “We plan and prepare as best we can but the unpredictable nature of geology can surprise us at any moment. So tunnel construction requires versatility, agility, efficiency and accuracy.”

Since late 2022, Poloni has needed all four of those attributes to successfully navigate the dark, dirty and cramped quarters of the Bjønnås Tunnel (Bjønnås) in eastern Norway.

One of seven tunnels being built for the 17.5kmlong, E18 four-lane motorway that will connect the towns of Langangen and Rugtvedt, the Bjønnås Tunnel is a 2.5km-long twin-tube tunnel that will have 10 x 15m-long cross passages and three technical buildings, each 16.8m wide.

Valued at NOK 5.2 billion (US$ 485 million), the E18 Langangen-Rugtvedt project is one of the largest ongoing infrastructure projects in the country.

To meet tight tolerances, high expectations and an intense pace, Poloni and his survey colleagues sought out enabling technology that would provide field autonomy to production crews and real-time analytical and reporting tools to maximise efficiency both in the tunnel and in office.

“In tunnel construction, ‘delay’ is a dirty word,” says Poloni. “No one wants to wait for surveyor support, but we can’t be everywhere at once. With the different sites and dynamic nature––literally––of the project, we wanted to adopt technology that would enhance tunnelling efficiency and tracking, reduce downtime and streamline data flows.”

Armed with Amberg Technologies’ Tunnel Solution, a cloud-enabled software suite that automates and simplifies tunnel work, Poloni and his team have been able to steadily advance the Bjønnås excavation, minimising downtime, reducing costs and optimising collaboration.

THE RIGHT TECH

From the outset, the project’s customer, Nye Veier, a company owned by the Norwegian Ministry of Transport, made it clear that technology would play a significant role––the design would be 100 percent model-based, 3D scans and 2D profiles would be required after every tunnelling step, a cloud-based common data environment and collaboration platform would be used to connect all stakeholders, and detailed digital reports would need to be produced daily.

With the varied technology on site and in the office, coupled with some design complexities, the Eiffage project team wanted a reliable and adaptable solution that would enable them to seamlessly move from design to completion with confidence.

As an avid user of Amberg Technologies, a Switzerland-based leading provider of civil infrastructure solutions, Poloni and his team chose to adopt Amberg Tunnel to execute the Bjønnås excavation.

“Amberg Tunnel is an all-in-one solution that not only handles diverse file formats, it automates stake out, blasting, profiling, and other tasks with the push of a button,” says Poloni. “It also provides task-specific data analytics and real-time data synchronisation. With all the variables involved in tunnelling, we knew Amberg Technologies would be the one constant we could rely on. Most importantly, the automated nature of the field software would give us the time to focus on complex survey tasks.”

CREATING AUTONOMY

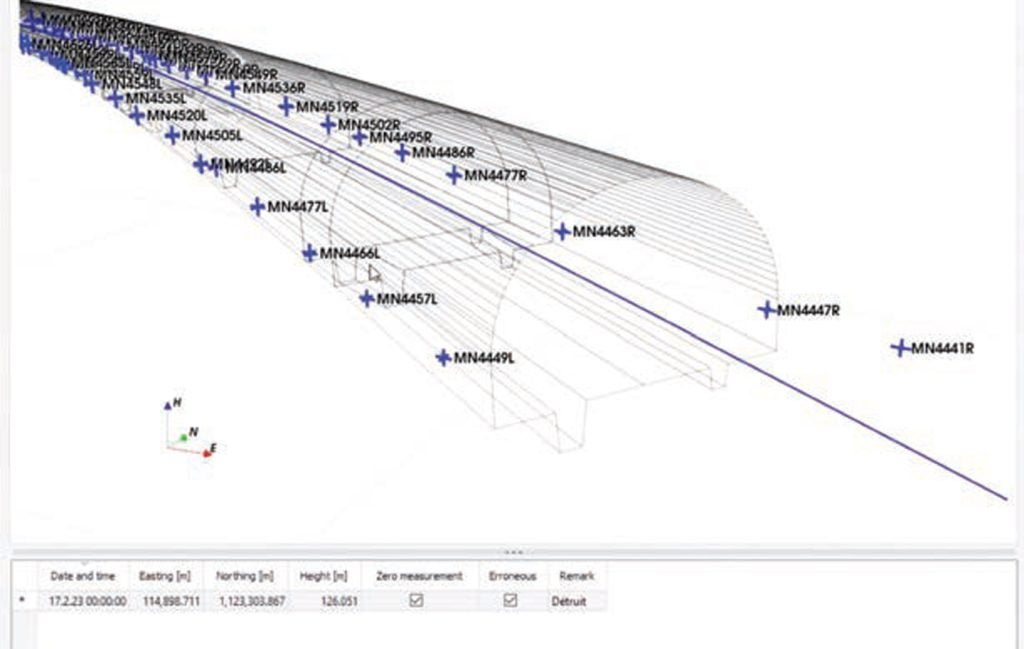

To accommodate the shorter range of their scanner, the surveyors establish project control by setting two control points every 10m on each side of the tunnel and measure the points with a Leica total station, enabling them to maintain a sub-centimetre control network. Each day they install and measure new reference points and import them into the Amberg Navigator software on the tablets, providing the georeferenced positioning needed for all tunnelling tasks.

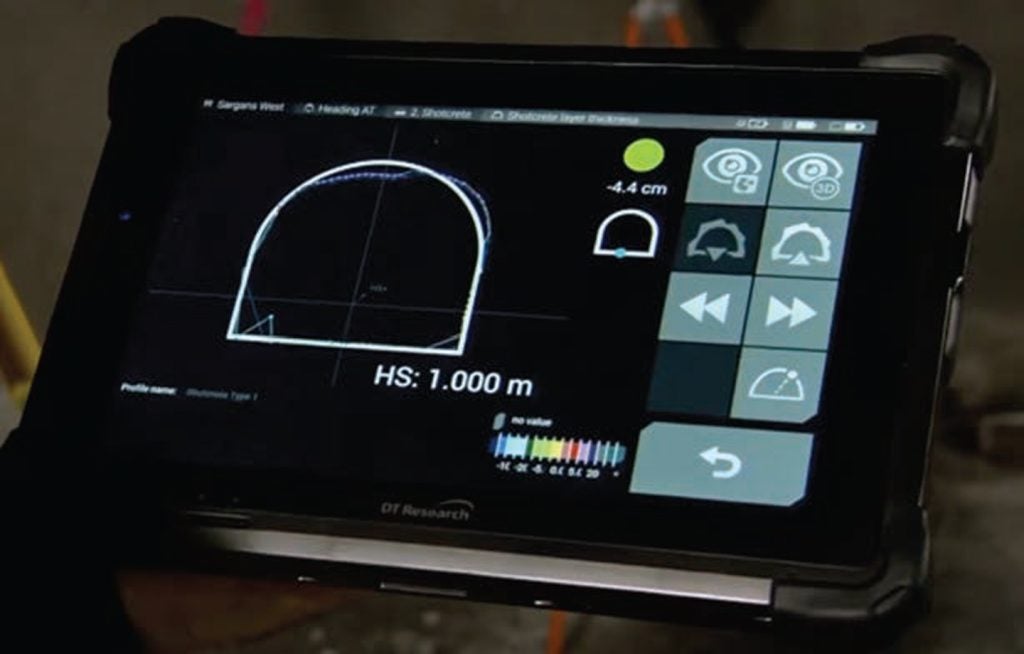

For production optimisation and efficiency, each four person crew were given one total station, one scanner and one tablet running Amberg Navigator, a fit-for-purpose software solution that offers 28 automated tunnelling tasks for heading guidance, excavation control and applying shotcrete linings.

“With Navigator, the tunnelling team can do everything in the field with pre-established, targeted workflows,” says Poloni. “They can position the drill rig, stakeout points, verify the design, check earthworks, and capture scans in minutes.”

With an approach that combines traditional total stations, 3D laser scanning and the automation and intuitiveness of the Amberg Tunnel solution, the survey team has been successfully supporting and directing a daily routine of blasting, drilling, confirming, and reporting for the past 18 months.

TUNNELLING, AUTOMATED

Directed by the survey and design data and Navigator’s workflows, blasting, shotcreting and drilling are semi-automated processes with real-time verification.

“A significant advantage with Amberg Tunnel is all of the construction guidance is based on parameters and reference points that we set and import into Navigator,” says Poloni. “We can define where a profile should be measured, how many points should be measured, at what interval, and at what accuracy. And we can completely lock it down so the production team just has to hit buttons as the software guides them. They can’t change the workflow or move forward if there’s an error or they haven’t done one step or measurement.

“It gives surveyors tremendous freedom to manage our tasks with the confidence that production will be done accurately and efficiently.”

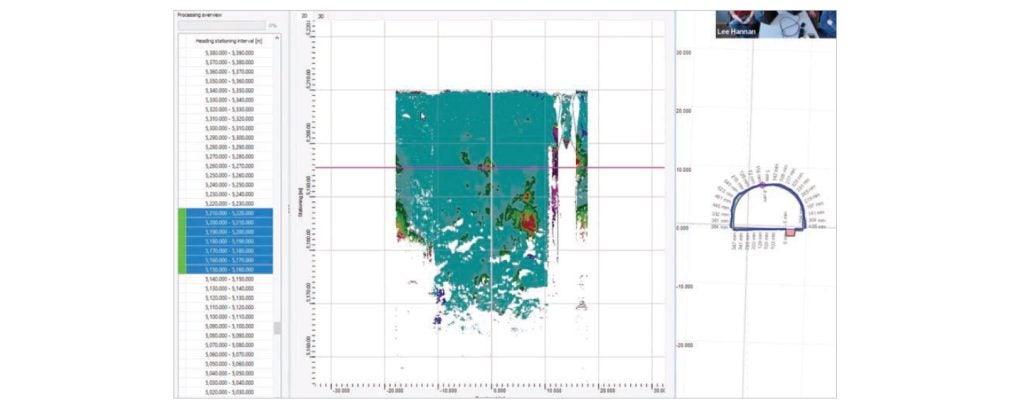

One primary job they perform is creating tunnel profiles of the excavated surface and tunnel face after each blast––a routine they complete four times a day after every 5m blast.

Using guided workflows in the Navigator software, they perform a resection with the total station to position the drill rig to drill blast holes along the tunnel face. Once each blast is complete, and it’s safe to approach the blast zone, they use the total station to measure a grid of points on the tunnel face. They then position the laser scanner by automatically measuring three mounted prisms, giving it absolute coordinates and tying it to the project’s coordinate system.

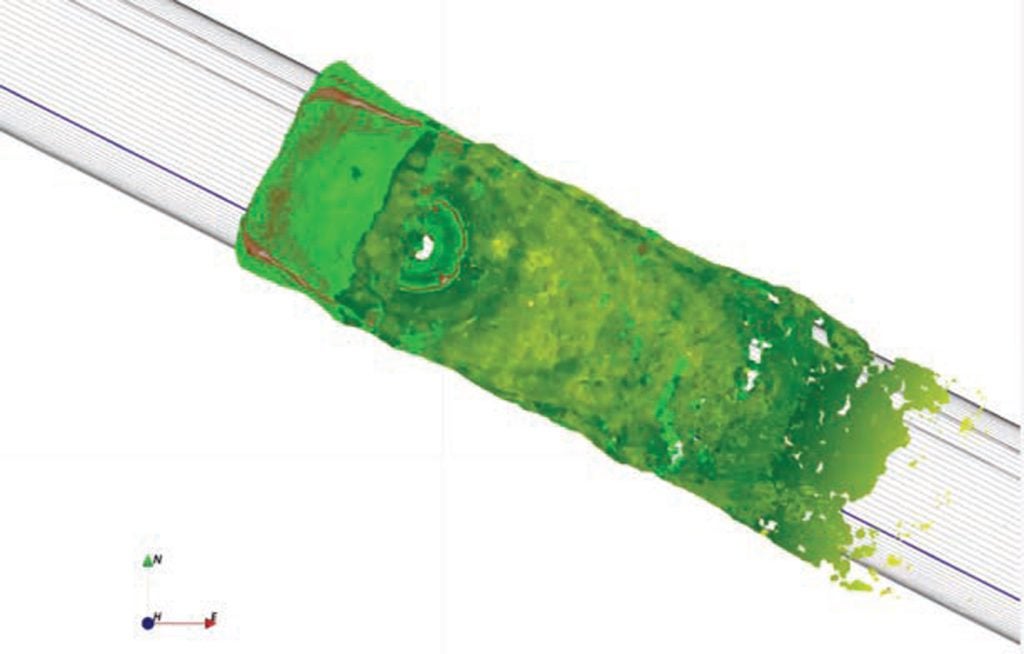

The scanner captures a 3D view of the tunnel face and excavated surface and immediately compares the point cloud measurements to the design on the tablet. That enables them to identify any overbreaks or underbreaks based on a pre-set, colour-coded heat map.

“Amberg Tunnel lets us set excavation design criteria and colour-coded deviations like red indicates -5 centimetres,” says Poloni. “With each scan, the software automatically calculates any design deviations from any point in the point cloud and produces a coloured map.

“So if they see any red on the map, they can use Navigator to aim the total station’s laser to that exact point relative to chainage and design position and see the corresponding overbreak or underbreak. If they need to scale the wall to fix an underbreak, they can see their progress in real-time until they’re aligned with the design. It’s incredibly helpful and keeps them moving.”

A scan also needs to be captured after each shotcrete layer is applied.

Similar to blasting, the production team uses project control to position the shotcrete machine and directs it to spray shotcrete based on the current theoretical design and designated rock class. Once the lining has been applied they georeference the scanner and capture the section to produce a colourised 3D view.

Using buttons on the tablet screen, they can select any point in the point cloud, calculate it and see the layer thickness in real time. The software will compare the previous excavation scan to produce a heat map. If there are any deviations from the design, they can select that AOI, use the total station’s laser to point to the specific area and either reduce the shotcrete or apply more. They can then continue to scan and check until the lining meets the design.

Without the processing automation of the software, teams would have to manually verify the shotcrete by drilling holes in the lining in a grid pattern and measuring its depth. That’s not only laborious, it would require more personnel and would be more susceptible to errors.

Additional to the blasting and shotcreting, there is also positioning and installing of varied bolts, such as rock bolts – a task the tunnelling team can do autonomously with a dedicated workflow in Navigator. Performing a resection with the total station, they establish the rig’s position and import the coordinates into the rig’s cab.

The operator then follows a pre-defined bolt plan to install the georeferenced bolts.

“Giving them the independence to blast, shotcrete, install bolts, and compare and calculate on the fly makes us so much more efficient,” says Poloni. “They don’t need to wait for us to advance, which greatly minimises delays. It also means we don’t have to be on site overnight, which positively impacts the budget.” Two-thirds of 2,500m has been excavated.

IN SYNC

Since the field data are synchronised with the office multiple times a day, Poloni and his team always know when they’ve received new measurements. They pick up the new data, Amberg Tunnel processes it, and automatically organises it into the proper site, proper heading, and proper excavation stage. From there they extract the data they need for design work, analysis and reports.

Per Nye Veier’s request, Poloni and his colleagues must provide daily reports detailing excavated rock volumes, shotcrete volumes and layer thickness as defined by the rock quality. They also want to have tunnel shape profiles every 1m, but depending on the tunnel section they’re working in, they offer scanning profiles every 5cm.

With the software, they can define at what interval they want to extract the profiles, and the point spacing to show as much tunnel detail as the client requires. And because they have a constant exchange of data between the office and the field, they are able to ensure the tunnelling is on point and the stakeholders are informed.

“The trustworthy automation in the field enables us to be in the office more, processing data, checking work quality, and delivering reports based on different clients’ needs, which can change on a daily basis,” says Poloni. “We are so much more responsive.”

The synchronisation is particularly advantageous when the dynamic nature of the tunnel and the geologic composition of rocks require a design change. Poloni can quickly access the latest scan profile, bring it into AutoCAD, make the necessary changes to the tunnel radius and bolt positions, and import it back into Amberg Tunnel. He can then send the new design back to the field, and in less than one hour the tunnel crew has the new design profile on their tablet. He follows the same process for any changes to shotcrete layers.

“We’re often adjusting the design, so the data synchronisation is a huge time gain for us,” says Poloni.

“Without it, I’d have to suit up to enter the tunnel, collect the data from the tunnel on a USB stick, bring it back to the office, import it, make all the changes, export it to the USB stick and take it back into the tunnel. With the real-time connection, it’s done in minutes and no one is left in the dark.”

As they strive to complete the Bjønnås excavation this Fall, there will likely be more uncertainty in what lies ahead, but Poloni is confident the Amberg Tunnel platform will offer them certainty in their work.