Samuel Thomas Huckle is a civil/mining engineer specialises in project delivery across Europe in varied roles in contracting, client’s engineer/advisory, and client positions. When not volunteering as Project Lead on a heritage rail project with a key tunnel requiring refurbishment, he is a Senior Engineer with Hochtief Infrastructure GmbH. In presenting to the BTS he was doing so in volunteer capacity and in doing so was a runner-up in the 2024 Harding Prize Competition with a paper entitled ‘Tunnel d’Yvoir – When tunnelling becomes a passion project’. It is published here with the author’s permission

This paper covers the first three years of development of the Tunnel d’Yvoir refurbishment project, located in Belgium. What was once a near-forgotten piece of railway infrastructure on the outskirts of a Wallonian town is now at the beginning of a journey towards once again serving its purpose. This daring project is to be undertaken by volunteers at a heritage railway, of which the author is a part, over the coming years.

In addition to discussing some of the technical content and steps in the project to date, the author aims to provide insight into how experience gained within the European tunnelling industry has been useful when applied in a pro-bono setting in the context of the heritage sector, more specifically to the reuse of underground infrastructure.

ORGANISATION

Established in 1988, the Patrimoine Ferroviaire et Tourisme (PFT), in French, and known as Toerisme en Spoorpatrimonium (TSP) in Dutch, is a society dedicated to the preservation of Belgian railway heritage. As part of its mission, the organisation (PFT/TSP) aims to refurbish and operate heritage rail vehicles originating from Belgium. For this purpose, they curate a dedicated museum in the town of Saint-Ghislain and operate a significant portion of the L128 – the Bocq Line located in the province of Namur.

L128: THE BOCQ LINE

The Bocq Line is a former Belgian State branch line that once served as a vital connection between the towns of Ciney and Yvoir, in the province of Namur. Initially rooted in industrial purposes, the rail line evolved over time to accommodate passenger use as well. Over a length of 20km, the line meanders through the picturesque valley of the Bocq River, from which it derives its name.

The PFT-TSP currently operates the section of the rail line between Ciney and Evrehailles-Bauche, covering approximately 16km of the total 20km historically in service. The remaining 4km-long section, leading into the centre of Yvoir, is part of a broader railway reinstatement plan of which the Tunnel d’Yvoir is a crucial component.

Of the total length of line, 2km is tunnelled, making it the rail line with the highest proportion of underground sections in the country to this day. Notably, the Tunnel d’Yvoir alone accounts for approximately 1km of these total of underground sections on the rail line.

THE TUNNEL D’YVOIR PROJECT

About the Tunnel d’Yvoir

The Tunnel d’Yvoir is a single-track hard rock tunnel that was commissioned to support the booming quarrying industry in the western and central sections of the Bocq Valley at the beginning of the 20th Century.

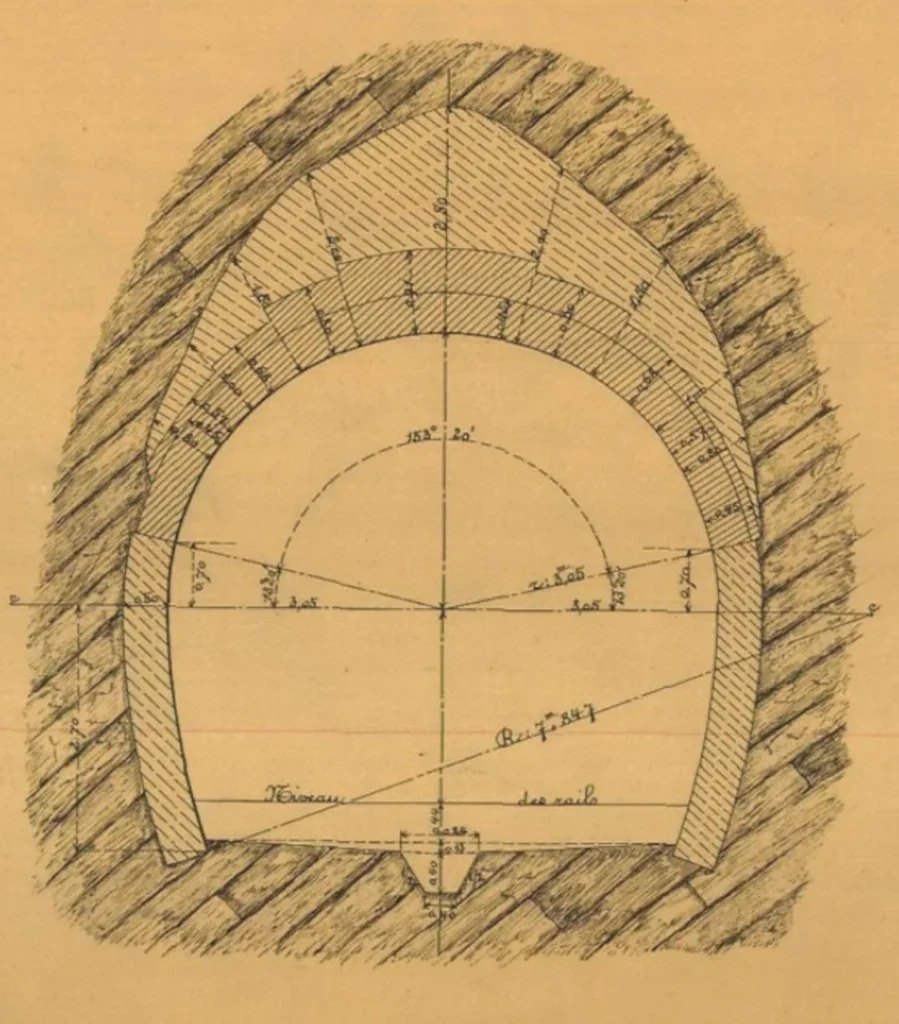

At 1,055m in length, the Tunnel d’Yvoir currently ranks as the 11th longest tunnel in Belgium and was inaugurated in 1906. Constructed using a combination of brick masonry and blockwork for support, it was excavated using the drill and blast technique, as was customary at the time.

The tunnel’s portals are designed in accordance with the prevailing architectural style of the era, featuring gothic-styled medieval castle-like elements. Positioned at embankment level, the portals are elevated in relation to their surroundings. To the west, the tunnel seamlessly connects to a stone viaduct that traverses the centre of Yvoir.

Unused since the cessation of commercial traffic in the 1960s, the Tunnel d’Yvoir was, however, maintained by the Belgian Army until the early 2000s as it was part of the strategic European rail network crucial during the Cold War.

Anecdotally, during the Second World War, the tunnel served as a secure overnight storage location for Hitler’s train during his journeys to and from Paris and Compiegne in northern France for the signing of the 1940 French Armistice.

The last inspection of the tunnel took place in 2003, and since then, it has largely remained unvisited, gradually blending back into its surroundings over time.

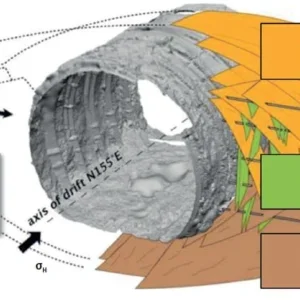

Tunnel and surrounding geology and topography

The geology underlying the construction of the tunnel consists of heavily slanted rock layers, composed of sandstones, limestones, shales, and silicates. Notably, the geological make-up includes the Formation de la Famenne, Esneux Formation de Ciney, Groupe d’Anseremme, and Groupe de la Station de Gendron.

The local topography exhibits significant variations along the tunnel alignment, with natural variations near the portals reaching up to 135m in cover at maximum.

At its midpoint, the tunnel alignment approaches an historically and actively quarried area with a drilling and blasting regime. The scale of the quarrying operation has expanded considerably since the early 1900s, resulting in a reduction in rock mass cover around a portion of the tunnel – reaching a minimum of 40m horizontally at its closest point.

Construction Method

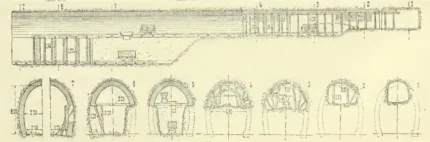

The Belgian Tunnelling Method represented the cuttingedge approach to tunnel construction in the region during the time when Tunnel d’Yvoir was being built.

This mined method involved creating the tunnel’s horseshoe geometry in two distinct phases of tunnelling. The process entailed placing brick masonry in the upper section to form the tunnel roof arch, followed by excavating the bench and invert sections, which were then lined with limestone blockwork. While it is likely that explosives were used in the advances, no specific accounts of such for this particular tunnel construction are currently known.

This characteristic is prominently visible today throughout the length of the Tunnel d’Yvoir. Although shotcrete has been utilised to reinforce the arched roof structure at several locations, a significant portion of the tunnel fully retains its original, as-built state.

Photographic evidence from the construction of another tunnel on the L128 rail line – the Spontin tunnel – clearly depicts a brick composition with a thickness of approximately 650mm in the arch. This measurement, however, is variable due to accounting for overexcavation occurrences and the subsequent backfilling required once the masonry arch was installed. This information aligns with details found on a contemporary technical drawing of the structure.

START OF ENGINEERING WORK Desk Study and Preliminary Investigations

The author’s involvement in the project commenced in late 2020, spurred by a report in the local newspaper announcing the desire of a group of volunteers at the PFT/TSP to reopen the tunnel to trains by the end of the decade.

Following a comprehensive desk study, conducted during the lockdowns due to the COVID-19 pandemic, there needed to be a preliminary walkthrough of the tunnel to gain a real insight into the condition of the structure, considering its last official inspection was performed in 2003.

The inspection, conducted in early 2022 by a team of PFT/TSP volunteers, aimed to provide an initial visual assessment of the state of the tunnel and evaluate the access requirements for the project. Occasional hammer tapping along the walls was performed to understand the integrity of the limestone blockwork.

Given the ‘as-is’ condition, the team exercised caution during the tunnel walkthrough, remaining alert and attentive to potential hazards.

Observations during visit

A variety of visible features and instances of degradation were observed throughout the entire length of the tunnel.

In general, the different pieces of evidence can be categorised as follows:

- Mechanically induced degradation of the lining;

- Cracking and displacement of the lining;

- Spalling and exfoliation of limestone blockwork and brick masonry;

- Age-related degradation;

- Environmentally induced degradation – (incl. exfoliation);

- Chemical alterations in the lining;

- Water/and sediment ingress.

Utilising the catalogue of structural ailments provided by Centre d’Études des Tunnels (CETU), in France, exfoliations were identified as requiring treatment due to their classification as structurally dangerous until proven stable. As a result, the decision was made to engage an impartial third-party engineering firm to officially assess and grade the tunnel in its current state. Subsequent safety approaches will be reassessed based on the findings of this evaluation.

Preliminary Conclusions of Project Start

After the initial inspection, several conclusions can be made, summarised as follows:

- The majority of the observed degradations are concentrated in the southern wall of the tunnel, predominantly in the central section of the alignment over a length of approximately 350m. This corresponds with the estimated location of the deepest points of the quarry pit.

- Numerous instances of exfoliation and degradation of the blockwork were identified, audibly confirmed by hammer tapping. These occurrences are often accompanied by surface discoloration, leading to a hypothesis that natural degradation resulting from the use of coal-powered steam trains in previous times may have occurred, resulting in damage due to chemical reactions.

- In the central section of the alignment, exfoliation is also present, often accompanied by brickwork exfoliation in the shoulder and upper section of the tunnel. This suggests a potential physical or stress-related lining issue. Fractures resembling the result of point loading have led to a reduction in lining thickness in numerous areas. Areas previously repaired with concrete also appear to fail due to the host brick failing.

- Seepage within the tunnel was predominantly observed in the last 400m, corresponding to the presence of an active spring in the vicinity, as identified in the hydrogeological data.

- At this stage, it is not possible to attribute any of the in-situ results to a specific cause of deterioration. The nearby quarry may contribute to an age- and stress-induced deterioration mechanism, of which the masonry is a visible consequence.

- An appropriate monitoring regime needs to be established and maintained throughout the project.

Next Steps

As this paper provides a snapshot of an ongoing project, it is crucial to emphasise that there is still work to be carried out over the coming years to achieve the heritage group’s goal. The chronological steps in this process are as follows:

- Address the close link to the operational quarry, engaging in joint discussions on the ownership of risk and historical effects. Ensure active participation of main stakeholders (municipality and quarry) in the further development of the project.

- Develop the funding model and timeframes for the next stages of the project.

- Establish a monitoring regime.

- Prepare for priority consolidation and repair work to be carried out on and around the tunnel.

- Obtain consent and permits to carry out works.

- Undertake design work in line with the end use aspiration and the situation of the surroundings of the tunnel.

- Ensure continuous funding for the project.

- Undertake continuous management of risks, including organisational risks.

- Build supply chain and contracting relationships.

- Proceed with works.

- Commission the tunnel as a modern piece of infrastructure.

A reflection on Pro-Bono Work

In this initial incursion into applying professional expertise in a pro-bono/volunteering context, several reflective points emerge that hold relevance for anyone contemplating a similar undertaking on a personal level:

- Empowering Collaboration: Inspiring others to feel supported and motivated toward achieving a shared goal.

- Personal Milestones Beyond Finance: Attaining personal milestones in confidence and professional value, transcending financial metrics.

- Demonstrating Passion for the Tunnelling Industry: Showcasing passion for the industry and leveraging a professional network cultivated within a learned society context.

- Technical Excellence with Limited Means: Striving for technical excellence and ethical standards using non-professional resources, aiming to achieve more with less, a challenge often less pronounced in larger projects.

- Cultivating Enthusiasm from Humble Beginnings: Generating enthusiasm and fostering interest in a project with modest origins.

- International Collaboration and Stakeholder Communication: Learning to collaborate internationally and communicate effectively with diverse stakeholders.

- Navigating Cultural Differences: Acknowledging the influence of different customs in various geographical contexts.

- Financial Strategy Development: Formulating financing strategies, employing subsidy models, and working towards common goals through research and development.

- Core Attributes – Passion, Discipline, Entrepreneurship, and Tenacity: Embodying qualities such as passion, discipline, entrepreneurship, and tenacity.

- Ethical Commitment in Pro-Bono Service: Recognising that providing assistance and advice for free demands an unwavering commitment to ethical standards.

CLOSING REMARKS

While this tunnel project initially appeared as a straightforward engineering refurbishment job, it has evolved into a far-reaching opportunity for all involved parties. The constraints of a tight budget and a strong sense of pride have cultivated an infectious level of commitment and dedication to a cause. Under more traditional circumstances, this endeavour might have been overlooked by most funding bodies and politicians. The moral of the story is that there may be transformative engineering projects close to you, just an interaction away from a game-changing contribution.

REFERENCES

- Boulogne, C. et al. (2015). Road Tunnel Civil Engineering Inspection Guide Book 1: from disorder to analysis, from analysis to rating.

- 1st ed. BRON: Centre d’Études des Tunnels (CETU).

- Boulogne, C. et al. (2015). Road Tunnel Civil Engineering Inspection Guide Book 2: Catalogue of deteriorations. 1st ed. Bron: CETU.

- Noël, J. (2020). “Chemin de fer du Bocq: dernier chantier sur les rails avant le tunnel.” Available: https://www.lavenir.net/regions/2021/01/11/chemin-de-fer-du-bocq-dernier-chantier-sur-les-rails-avant-le-tunnel-NTH5DLMMX5ESPCE3AOWOCH7ZPU/

- Service de Sécurité et d’Interopérabilité des Chemins de Fer, 2021. Guide Pour L’Introduction Aupres de L’Autorite de Securite d’Une Demande D’Autorisation de Mise en Service ou d’un Dossier de Conception, Concernant des Installations Fixes. 0.1 ed. Brussels: Service de Sécurité et d’Interopérabilité des Chemins de Fer.

- Villevert, E., (1866). Chemins de fer, construction des travaux d’art, tunnels, maisons de garde, barrières, plates-formes, ballast et voies. 2nd ed. Paris: DUNOD.