Austrian electric utility Verbund has begun excavation work on a 5.6km pressure tunnel, a key component of the €370m ‘Kaprun 2029’ hydropower modernisation project in Austria.

The tunnel will support long-term energy production at the Kaprun-Hauptstufe power plant by ensuring a stable water supply from the Wasserfallboden reservoir to the facility in the valley.

The project reached a milestone on 18 February 2025, when the tunnel boring machine started operations.

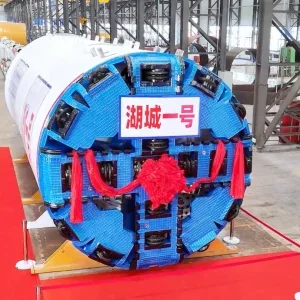

The tunnel boring machine, previously used in the Limberg II and Limberg III projects, has been modified for this phase of construction.

The machine consists of a 100-tonne cutterhead with a diameter of 6.90m, fitted with 42 cutting rollers, each measuring 43cm and weighing 130kg.

The entire system spans 190m and weighs 1,200 tonnes. Its components were delivered in 90 separate shipments and assembled in an underground cavern over eight weeks.

Verbund hydro power managing director Michael Amerer said: “We are continuing on the path taken by the heroes of Kaprun after the Second World War for the reconstruction of Austria. Today, we have driven the first metres of the new pressure tunnel – an important moment for Verbund.

“This pressure tunnel is the centrepiece of our project, which will upgrade the entire power plant to the latest state of the art by 2029, so that we can continue to supply all of Austria with green electricity and efficient flexibility from hydropower in the future.”

Verbund project manager Maria Leo: “We are pleased that the preparatory work has gone so well and that it is now starting.

“The geological conditions for the advance are well known and the tunnel boring machine and the team are already familiar with our mountains from previous projects. Almost all of the work will be carried out underground. This means that the impact of the construction work is reduced to a minimum.”

With excavation now underway, the machine is expected to advance at a rate of 15m per day, reaching the new surge tank within a year.

The completed tunnel will have an incline of 0.50% and an excavation diameter of 6.9m. To facilitate the excavation process, a rail system will be installed inside the tunnel.

Approximately 200,000m³ of excavated material will be transported via conveyor belts from the cutterhead to a transfer station at the Limberg valve chamber before being moved through existing tunnel infrastructure to a designated disposal site.

The headrace tunnel is scheduled for completion by the end of 2027.