With only tight space available for construction work at either end of the Silvertown road tunnel, in London, the efforts to launch and re-launch the single Herrenknecht TBM working on the twin tube project was always going to be an interesting technical challenge.

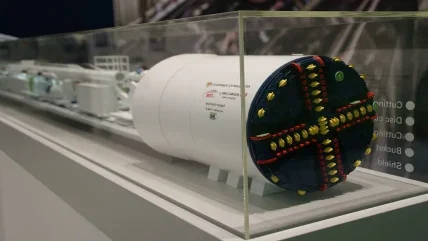

Add to that the large size of the solitary machine – at 11.91m-diameter it is the biggest to have worked in London and the UK. There are larger TBMs that have bored tunnels in the world, but they are not abundant; Silvertown’s TBM, named ‘Jill’, has some ranking in international levels.

But it was at a local spot in London, in a ‘peanutshaped; shaft on the north shore of the River Thames, that saw the first challenge for the machine: erecting the TBM in the short shaft and employing a pressure ring launch system to get it underway, boring from Silvertown southward to the reception shaft in the Greenwich peninsula, not far from the O2 arena (or, ‘Millennium Dome’).

The engineering challenges of designing and installing the pressure ring launch system were detailed in a Harding Prize Competition paper this year, publishing recently in T&T (June 2023). The system in usual for tunnelling in London, and only used on some projects elsewhere.

Once successfully proven in the Silvertown shaft, and lessons learned, the system was then moved to the Greenwich shaft. There, it was redeployed, ready to relaunch the TBM back to where it started, by boring a second, parallel, 10.8m i.d. tunnel under the river.

But, before that could happen, there was another uncommon technique employed in tunnelling in London: the single TBM was U-turned in a tight area in Greenwich, to be moved, realigned and prepared for the return drive. Nitrogen ‘skates’ were used to rotate the TBM sections in the reception chamber, the first section being turned 180° in only one day. The air cushion system was developed by Herrenknecht and its partners.

All that happened earlier this year but the scale of tunnelling machine and the uncommon support systems engaged for the project offer sights to behold – and not forgotten, as the TBM is well underway toward finishing its second 1.1km-long drive.

Beyond the technicalities, the project itself is different – it is a public-private partnership concession with the client, Transport for London (TfL). The contractor is Riverlinx CJV, a construction joint venture comprising Ferrovial Construction UK, BAM Nuttall, and SK Ecoplant.

The full length of Silvertown road tunnel project is 1.4km-long. The tunnel is due in service in 2025.