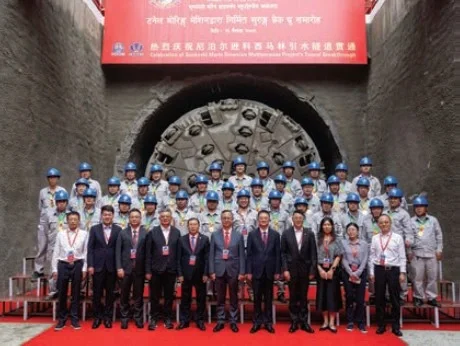

Nepal has been long looking forward to the societal and economic benefits to come from the Sunkoshi Marin Diversion Multipurpose Project (SMDMP) and so the recent tunnelling success with TBM breakthrough to finish the headrace bore – early – proved a milestone moment for the project and country.

In early May, the 6.4m-diameter Robbins doubleshield TBM achieved breakthrough to complete the mechanised bore work on the 13.1km-long water tunnel some 11 months earlier than had been scheduled – despite many challenges. Main excavation works for the multi-purpose project got underway when the TBM was launched, in late 2022.

The refurbished double-shield was used previously, at smaller diameter and to great success, on the Bheri Babai Diversion Multipurpose Project, also in Nepal. That tunnel drive was 12.2km in length, and the machine finished the drive in 19 months, almost one year ahead of schedule – and also despite many challenges.

Sunkoshi Marin, the contractor building the multipurpose project – involving both hydropower and irrigation use of water – is a joint venture of China Overseas Engineering Co (COVEC) and China Railway No2 Engineering Group Co (Bureau-2). The JV – known as B-2/COVEC – was awarded the contract in early 2021 by the Nepalese Department of Water Resources and Irrigation – which is part of the Ministry of Energy, Water Resources & Irrigation.

The project will tap the waters of the Sunkoshi River via hydraulic structures, including a concrete diversion weir and also a desander to remove silt. From there the flow will be conveyed by the headrace tunnel to a 28.6MW surface hydropower station, on Marin River, and then also be used for irrigation of agricultural fields in the districts of Dhanusha, Mahottari, Sarlahi, Rauthat and Bara in the Terai Plains.

The Nepalese Government has declared the multipurpose investment to be a National Pride project.

Geology for the TBM’s headrace bore was challenging and conditions were varied, says Robbins. There was highly jointed mudstone, sandstone, conglomerate, quartzite, granite, and even more, including major fault zones, encountered early in the drive. There was also collapsing and squeezing ground.

With the varied Himalayan geology, and a maximum overburden to the headrace is 1320m, the TBM had a tapered shield, enclosed cutterhead, overcut capability and high thrust to help reduce risk from squeezing ground. Still, it was stopped twice into the drive – first, halted by jointed sedimentary rock (after approx 2150m), and, second, then caught fast by collapsing and squeezing ground (after approx 4670m). Bypass tunnels were needed, and executed by the JV’s experienced crew. Time taken to free the machine was nine days and 27 days, respectively, on those stoppages.

Yet, despite those challenges there was very good tunnelling progress overall, and advance rates that improved.

Early, on the drive, there was a best week of 224.6m and best day of 36.6m, and then by Q3-2023, some 8km into the drive, there was a best month of 1224m (which topped the machine’s best month of 1202m on the Bheri Babai drive. Then, in March this year, shortly before the end of the bore for Sunkoshi Marin, the TBM recorded a best month of 1503.3m and best day of 72.6m.

Jin Haikuan, the B-2/COVEC deputy project manager and also the TBM production manager, said: “One of the highlights is that this machine integrates the overall structure of the 5.06m-diameter TBM from the Bheri Babai project. After upgrading to 6.4m-diameter, all now front shield components were not assembled in the factory. Instead, we adopted Onsite First-Time Assembly (OFTA). This was very effective, and I find it particularly noteworthy.”

Robbins’ president, Lok Home, attending the TBM breakthrough, said: “B-2/COVEC and Robbins have successfully introduced and spread TBM technology in Nepal.” He added: “To have these good performances on these first two projects is a really good thing for the country and our industry.”