With the delayed and somewhat-muted Japan 2020 Olympics and Paralympics only having concluded in August and September 2021 respectively, it might seem a little early to be thinking about the 2032 games. But their venue, Brisbane, Australia, was announced on 21 July 2021; and when on 6 August TBM Else, followed shortly by her TBM sister Merle, excavating for Brisbane’s Cross River Rail project broke through into the cavern of what will be the new Roma Street station in the central business district (CBD), Brisbane’s politicians and press made the most of it.

“Twin tunnels now connect the future Roma Street and Woolloongabba Cross River Rail stations, which were important selling points in our bid to secure the 2032 Olympic and Paralympic Games” said Queensland Premier and Minister for Trade Annastacia Palaszczuk. “This is the same route people will travel in the future to get to where they need to be, including between the athletics and swimming events at the 2032 Games.” It only helped the connection that the new Roma Street station will also include an indoor sports area, as a key Olympics venue, and that Woolloongabba is better known to sports fans worldwide as The Gabba – Brisbane’s test-cricket ground, which will also be hosting Olympic events.

Even in sports-mad Australia there are of course much more pressing reasons than the Olympics for the Cross River Rail project. The population of southeast Queensland is forecast to grow from 3.5 million today to 4.9 million in 2036. Over 80% of that growth is occurring outside the Brisbane area. Roughly 45% of job growth, however, is forecast to be concentrated inside it. The people will need to get to the jobs. Better transport connectivity will be crucial. (The projections were made before the pandemic; but even if post-Covid working practices retain an increased element of remote working, the need for better transport will remain).

The current rail network is already nearing capacity. The Brisbane River in particular is an obstacle. There is only one inner-city rail river crossing, the Merivale Bridge, and that is already reaching maximum capacity. This project will unlock the bottleneck by delivering a second river crossing which will be underground. The importance of breaching the water body is reflected in the name of the entire project, Cross River Rail, though it involves considerably more than just the crossing.

It consists also of 10.2km of new rail line including 5.9km of twin tunnels running under the Brisbane River and CBD. Currently four stations serve the Brisbane CBD; this also limits the possible number of trains. Four new, state-of-the-art underground stations will be added, at Boggo Road, Woolloongabba, Albert Street and Roma Street. At Roma Street, the line will interchange with existing surface lines and Exhibition Station – which currently opens only occasionally to serve major exhibitions at the Royal National Agricultural and Industrial Association (RNA) showgrounds, but it will be upgraded to allow it to enter full-time operation.

“As well as that, the project will upgrade six stations between Fairfield and Salisbury, deliver three new stations on the Gold Coast and introduce a new world-class signalling system to the wider South East Queensland rail network,” says Tai Luong, Area Engineering Manager, Tunnels & Woolloongabba Station for the Cross River Rail Delivery Authority. “It is more than just a rail project. Cross River Rail also presents opportunities for urban renewal and precinct development at each of its major station locations. It will transform the way Queenslanders travel.”

The line will connect with new roads and new busways as well. Once Cross River Rail is operational, 36,000 passengers are expected to use Roma Street each weekday to transfer between buses and trains. An initial plan to move the bus station there underground to form a seamless connection with the new rail platforms was changed when investigations showed that commuters were more likely to change between the two if the bus station remains on the surface. It will be upgraded to bring it in line with the look and feel of the new underground station and the main station plaza, which will be a win for commuters and a better value for money outcome.

At a capital cost of AU$5.4 billion (US$3.97bn), Cross River Rail is expected to be the largest transport project ever built in Queensland. The business case has benefits of the project expected to exceed costs by AU$1.9 billion (US$1.4bn); for every dollar invested, the project is projected to bring in AU$1.41. Construction will bring around 1,500 jobs per year.

Three major packages of work make up the project. The consortia for the contracts were announced in April 2019. The Tunnel, Station and Development (TSD) package, which includes the underground section of the project and the construction of the four inner-city stations, is being delivered by the Pulse Consortium led by CIMIC Group companies Pacific Partnerships, CPB Contractors and UGL, with international partners DIF, Bam and Ghella. The other packages are the Rail, Integration and Systems (RIS) alliance and the European Train Control System (ETCS) contract.

Early works – geotechnical investigations through to borehole drilling, subsurface public utility investigations, baseline monitoring and demolition works – began in August 2017. So too did construction of the temporary coach terminal at Roma Street. In late 2019, major construction started.

Cross River Rail’s 5.9km of twin tunnels will stretch from the project’s southern portal at Dutton Park, under the Brisbane River and CBD to the northern portal in Normanby. The parallel twin tunnels are segment lined, with cross passages every 240m. At their deepest, at Kangaroo Point, they are 58m below the surface.

The two TBMs are working in parallel, excavating from Woolloongabba north to Normanby. The remaining, short 870m section of tunnel from Woolloongabba south to Boggo Road is being excavated by roadheaders.

Cross passages are being mined by excavators, rock hammers, and drill and blast; the latter is the preferred method within the TBM tunnels as it reduces overall construction time. Where blasting is not deemed feasible, manual excavation with a rock hammer is the fallback. Each cross passage is approximately 5.8m wide, 5.8m high and 6m long. Sixteen of them are permanent to act as emergency access or escape points; additional temporary cross passages facilitate in-tunnel access during construction.

The TBMs launched from a shaft at the Woolloongabba site: Else launched in February 2021, Merle a month later. They are twin-shield machines supplied by Herrenknecht, 7.23m in diameter. The tunnel intrados is 6.37m diameter – the extrados is 6.91m – and the precast lining segments are 0.27m thick. They are rebar reinforced and six to a ring including two shorter keystones.

“Further out from the city centre the roadheaders are encountering conglomerate and siltstone/sandstone in their tunnels,” says Luong, “but the TBMs are working through Brisbane’s notoriously hard Neranleigh-Fernvale rock beds and Brisbane tuff rock. Given that situation, no hyperbaric interventions are needed, and no hyperbaric chambers are installed on the TBMs. Over 240 boreholes along the tunnel alignment have given us a full geotechnical model.”

The 25,000 concrete lining segments are produced by Wagners off-site, at their plant in Wacol, around 17km from Woolloongabba. They are producing 500- 600 segments per day, initially on a day shift only but moving to day and night shifts as the project gets into its stride, and delivering them by truck, 40 trucks each night, to a holding yard at the Gabba where they are loaded by forklift onto MSV to delivery to the TBMs. They are edge-lined with waterproof gaskets and connected with dowels and speedbolts.

“The spoil goes by conveyor belt back to an acoustic shed, again at the Woolloongabba site. From there it is sent by truck to various construction locations including Brisbane Airport and the Port of Brisbane.”

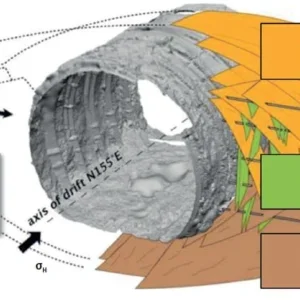

Luong’s remit includes the Woolloongabba station cavern. “Station shaft sizes vary between the four new underground stations” he says. “On average, they are around 30m below ground level. The caverns are 280m long, except at Albert Street where it is 10 metres longer. They are an inverted ‘D’ shape, about 15m high and 23m wide.

“The temporary retention structures for all the station boxes have been constructed with soldier piles supported by stress anchors. The drop shafts, also temporary, are primarily being used for removal of the excavated cavern spoil by kibble crane.”

The Boggo Road cavern is less deeply buried than the others. Its roof lies just below the surface under existing public transport infrastructure, including above-ground rail lines. For this reason, canopy tubes were installed to reinforce the cavern roof. Before excavation, 19 steel tubes were drilled horizontally in an arch shape to form a pipe umbrella. Each tube was 506mm in diameter and 102m-long; once inserted they were filled with grout. The cavern was then excavated beneath the resulting concrete arch, which gave additional support to the roof.

Part of the Albert Street cavern was in fact excavated by TBM. In June 2021, TBM Else tunnelled beneath what had so far been excavated of the cavern. It carried on through and once it was clear the cavern excavation team blasted their way down to the tunnel, completing the lower section of the cavern. The advantage was that the TBM itself had excavated a good proportion of the cavern’s final cross-section – about a quarter of it in fact – which meant in turn that the spoil from that section was sent by the TBM’s conveyor back to the Woolloongabba portal, instead of having to be craned out and trucked through the inner city. Around 2,000 truck movements were saved. Altogether, the TBMs will mine around 290,000m3 of spoil.

“The traverse below the Brisbane River has been one of the project’s most challenging aspects so far,” says Luong. “The stretch under the Brisbane River is about 400m long, and 42m below the river. While they were tunnelling beneath the river, crews undertook probe drilling around 35m in front of the TBMs, which allowed our workers to determine what type of geology they would be passing through. The TBMs can change to single-shield mode, which allows them to excavate more safely in areas of potentially low rock strength, and there are systems in place to ensure that the machines and tunnels are watertight. Our lead TBM, Else, was able to complete her tunnel under the river in about three weeks. That was a massive milestone for the project.”

USING RECYCLED GLASS

An interesting initiative on the project is that it is trialling a type of sand made from recycled glass as pipe-bedding fill for stormwater pipe relocation works. The first trial was at the Boggo Road site in 2020, and a second trial at Mayne Yard has also proven to be a success. The crushed recycled glass is used in the same way as any other sand or aggregate. Because the glass has been reduced to the granular size, shape and consistency of normal sand it does not cut hands or cut into pipes.

This sustainable method reduces the amount of glass ending in landfill and also reduces the amount of sand or gravel from excavation. Cross River Rail will use around 10,000t of the material, which represents about a quarter of the glass sent by southeast Queensland to landfill each year.

“As of September 2021, TBM Else has travelled 3,017m, and TBM Merle has gone 2,614m,” says Luong. “Both have passed through the Roma Street cavern and have begun the final leg of their journey to the northern portal at Normanby. TBM progress has averaged around 20 or 30m per day, and both machines are expected to break through at the northern portal by the end of the year.

“And the roadheaders have excavated the rest of the twin tunnels from Woolloongabba south to Boggo Road. The project so far is on course for commissioning in 2025.” That should be in plenty of time to prepare for visitors to the 2032 Olympic Games, assuming we have no more disruptions from an erratic pandemic.