“My career began in 1968 when I was still a student working on the Victoria Line with the Mitchell Brothers,” he explains. Last year he was appointed Head of Tunnelling at Laing O’Rourke. During this journey, he has worked for a who’s who of UK engineering firms including Mowlem, Nuttall, Balfour Beatty and AMEC.

“Some of the most notable projects I’ve been a part of are Cairo Wastewater, where I was with Lilley Misr International and I was also one of the main construction people on the Channel Tunnel planning and developing the initial marshall tunnels under Shakespear Cliff, procuring and constructing the seaward running tunnelling machines and bedding them in on their drive towards France,” he remembers. “I became head of tunnelling for AMEC after we completed the Westminster to Waterloo section of the Jubilee Line, a position I held for some seven years. Then I spent about 18 months at Jacobs doing somevery interesting consultancy work, before coming to head up Laing O’Rourke’s tunnelling.”

With Laing O’Rourke’s involvement in several major consortiums, Peter’s position at the company is an exciting one, especially as until his appointment, there was no specific tunnelling division in the company. There are currently seven key people on his team, a number which will increase as their workload develops. “I’m heading up their international tunnelling efforts from here, we’re currently tendering some major work in Australia, as well as looking elsewhere in Hong Kong and the world.”

Peter found it hard to resist the lure of a new role with Laing O’Rourke. “It was the sheer dogged determination of Laing O’Rourke and the senior people who interviewed me to develop the world I love that brought me to this job,” he explains. “Tunnelling is something that I can’t do without, it got in my head and it’s stuck. So anybody that’s going to put the passion behind what I believe in gets my vote. So I’m here!” he laughs.

“We believe that we can achieve what we say we want to do in Laing O’Rourke, and I know the next twelve months will be when we see the huge benefits of what we’re doing and we’ll be a major force,” he says.

One of the JVs Laing O’Rourke is part of is with Bouygues and Strabag. “The Laing O’Rourke/Bouygues/Strabag joint venture is huge in experience and, we’re probably one of the robust consortiums going for Crossrail at the moment.”

Of all the places that Peter has worked, London remains his favourite. “I like London due to the familiarity. I’m proud to be a London engineer. There are a lot of things to be done in London and to be part of that infrastructure development is fulfilling.”

Along with his work on the Cairo Wastewater where innovation was required to complete the project, “We had to pretty much invent the way we worked as spares were sparce so we had to locally manufacture much of what we needed.” The other High Point of his career is his involvement in the Jubilee Line at Westminster and Waterloo. “That was a really interesting project and was probably the most difficult one I have ever done. It was far more difficult than the likes of the Channel Tunnel,” he says.

One of Peter’s many impressive accolades is being in charge of the AMEC Ring Main Project which struck up a World Output Record for segmentally lined tunnelling. “We put 501m of tunnel in to the ground in a week, in just five days in fact.No one’s been near it since. It’s still unbeaten.” According to Peter, technological advances were not behind the success, “It was bored with just a normal TBM with segment lining behind it.” He gives the credit to “a good team and tremendous effort from all.”

Peter has also made impressive inroads above land. “I put together the The All Party Parliamentary Group for Underground Space (APGUS) with Helen Nattrass,” he says. “It was very difficult to do, you don’t just walk in to places like that, we had to tread water carefully and do it one step at a time, often one forwards, two backward. That was my key achievement as Chairman of the BTS and that’s still going strong.”

Safety for workers is an area of tunneling that Peter feels strongly about, and an area that he has seen evolve for the better. “I’m old world, I come from compressed air and open face working with no alternatives,” he says. “We have slowly but surely built the world of tunnelling up in my career and we’ve created less risky methodologies as time’s gone by. We have developed an ethos now where safety is king and we have a no nonsense approach to safety risk. The days of tolerance of impetuous behaviour are gone.

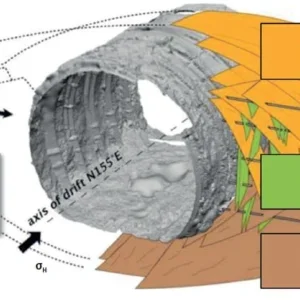

“With the growing use of closed face TBMs we’ve sealed the working face off with a bulkhead and we can now maintain pressure on the face without resorting to compressed air. As long as we understand what we’re doing which is very important, modern methods can considerably de-risk tunnelling operations. It’s where people don’t understand what’s going on in front of them with these machines that the problems start.”

Peter has not only seen but been a part of many developments in tunnelling duringhis career. He introduced the use of wet spray shotcrete in the UK on the Jubilee Line. “It was under my control on that project, and since then its use has become internationally accepted as being the way forward.” He also introduced the two-part annulus grouting system to the UK on the Channel Tunnel. He regards the international tunnelling community as being another vivacious area of development within the industry.

Away from tunnels, Peter is an avid yachtsman and has his own boat mooredin the UK. “Sailing is a passion of mine, it keeps me alive. It’s real adrenaline instead of this stuff we deal with on a daily basis!”

Peter South