In Mumbai, a JV of J Kumar and Michigan Engineers Private Ltd (MEPL) is helping to improve the sewerage network with extensive tunnelling work using TBMs of different types to suit the differing rock geology on adjacent sections of the project.

The Mumbai Sewer Disposal Project (MSDP) Stage II project involves construction of two Priority Sewer Tunnels (PST) – the 5.8km-long PST-1 and the 4.7kmlong PST-2, respectively. The MSDP project involves constructing shafts and upstream connections to reduce wastewater flow into existing collector sewers and decommissioned pumping stations.

The project owner is Brihanmumbai Municipal Corporation (BMC).

PST-1

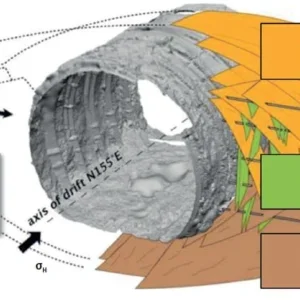

Along the alignment of PST-1 sewer tunnel, the geology comprises weathered/fresh breccia and basalt.

Terratec supplied a 3.85m-diameter rock slurry TBM to the contractor. The machine was launched earlier this year, the Malad Shaft S07 Pumping Station. Progress at fresh rock is expected about 14 rings/day.

The TBM is constructing a tunnel of 5+1 universal type segmental rings. The segments are 200mm thick and 1200mm wide.

A slurry system controls excavation face pressure and the cutterhead is equipped with 23 x 15” replaceable disc cutters. The machine has a high-speed main drive capable of 8rpm, and an active articulation system accommodating a minimum curve radius of 250m.

Its hydraulic main drive includes a shield integrated manlock.

The Terratec Slurry Transportation System and Slurry Treatment Plant were also supplied for slurry removal and treatment, which it says is an effective combination to achieve efficient and cost-effective excavation over long distances.

PST-2

Along the alignment of PST-2, the geology comprises silty sand, silty clay, boulders, breccia, and clay with gravel.

The alignment also has to negotiate a sharp road interchange area and also piled foundations for an elevated metro line.

For this tunnel drive, the contractor is use another Terratec machine – a 3.14m-diameter rock earth pressure balance TBM. The EPBM has a mixed type cutterhead with 27 x 17” back-loading cutters. The highspeed main drive can support up to 8rpm.

The machine’s active articulation system is designed to negotiate an even tighter minimum curve radius of 95m, helping to work through the congested areas of road interchange and piled foundations without needing intermediate shaft construction.

The tunnel lining is 4+1 universal type segmental rings. The segments come in different lengths – 1000mm and 650mm – to help construct the concrete rings for the tight curves.