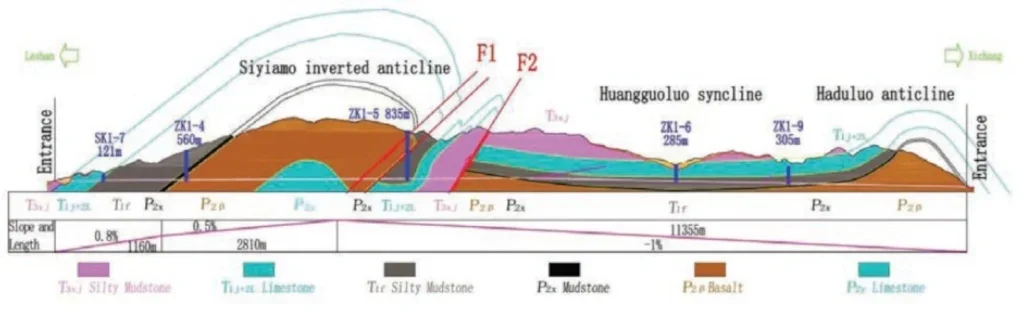

Prediction of bad ground ahead of a 15km-long, twin-tube four-lane dual carriageway highway tunnel through the Daliangshan mountainous region of Sichuan, in China, was giving the Project Director great cause for concern. The risk of encountering extreme geological conditions was high, ranging from: high water ingress and karstic voids in the predominantly limestone deposits; squeezing ground in reaches of 5MPa-20MPa mudstone; and, major fault features in basalt layers. Up to 93% of the long tunnel excavation runs through poor conditions of Rock Classes 4 and 5.

Running blind into any of these conditions while advancing the 105m2 open face drill & blast headings would put the workers, the equipment, and the entire project in jeopardy in terms of safety, increased costs and whole project delays.

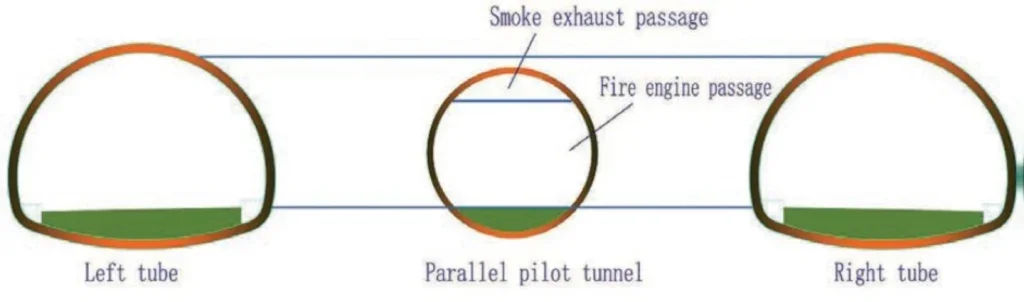

The solution for Project Director Lan Fu’an was to promote a completely new and revolutionary approach to highway tunnel design, excavation, and operation. For the first time in highway design, this long expressway would start with excavation of a central, full-length pilot between the main traffic tubes. This approach would change the design and excavation sequence of the project and of the fire-life safety, maintenance, and traffic management in operation.

The central pilot would allow for investigation of the geology and preparation for excavation of the two main tubes, and provide space to treat zones of poor ground both ahead of the pilot tunnel face and laterally into the alignment of the two main tubes.

Fortunately for Project Director Lan, and after months of discussion and convincing, the proposal to construct a 15km-long full-length pilot tunnel for early geological investigation was approved. This was a relief for the safety of workers as well as reducing risks associated with the overall project.

While central pilot tunnels are well known for long twin-tube railway links, this is believed to be the first full-length pilot tunnel for a highway project – and it took some convincing for the proposal and its added cost to be approved. As part of the decision-making process, the option to include the pilot raised the Daliangshan No 1 Highway Tunnel project to be a provincial government priority in Sichuan, and also an important national research project; this would bring research programmes and new design developments to the highway link project.

PROJECT DESCRIPTION

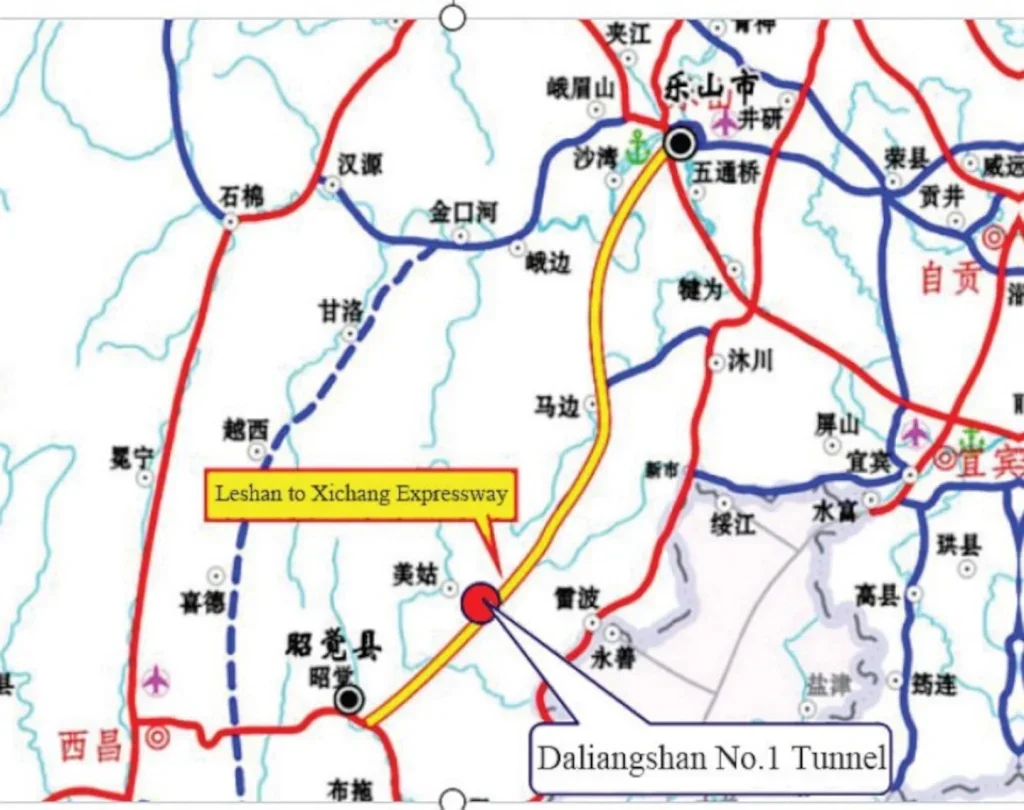

The Daliangshan No 1 Highway Tunnel is the longest of several on the new Lexi Expressway where approximately two-thirds of the 152km-long route runs underground through twin tubes. In the mountainous region, most of the remainder runs on high-level viaducts that bridge narrow valleys.

The full 33.5 billion Yuan RMB project (approx US$4.6 billion) will reduce the current journey time between the towns of Maibian and Zhaoieu from 5 hrs to 1.5 hrs. The investment is aimed to improve the quality of life, economic prosperity and connectivity of the citizens who live and survive in the remote valleys, towns, and rural areas of the Daliangshan Mountain region.

Project Director Lan is also Chairman of the Sichuan Lexi Expressway Company, part of the huge Shudao Group of China that is ranked 389 on the Fortune 500 list of largest companies in the world. As a subsidiary of Shudao, the Lexi Expressway Company is responsible for construction, operation and maintenance management of the Lexi Expressway which will be part of a network of existing expressways totalling some 9,800km in Sichuan.

Other parts of the Shudao Group have built more than 10,000km of expressways, 7,500km of rail, 3,000 bridges, 200 long tunnels, 19 hydropower projects and additional solar and wind power projects, and have worked abroad in 30 countries.

CONSTRUCTION CHOICES

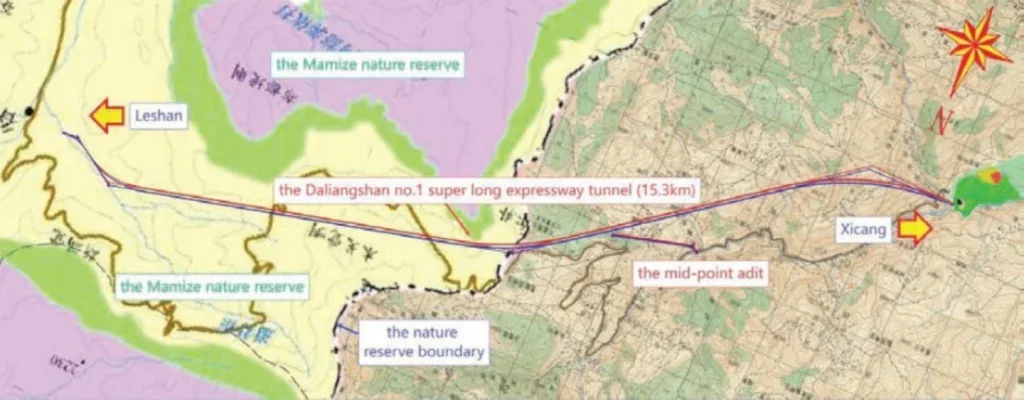

Daliangshan No 1 tunnel is the longest highway tunnel currently in south west China and crosses two well defined seismic fault lines that would undoubtedly present extremely adverse geological conditions. Hazards to the project were heightened by the fact that the alignment runs under a national reserve with only one intermediate adit permitted, and there excluded the possibility of vertical boreholes to investigate the tunnel’s overburden of a maximum 2,080m.

The mountainous terrain is a challenge. At present, to drive from one end of the tunnel to the other on the local roads takes more than an hour; the trip will take only 15 minutes through the tunnel when it opens.

The limitation of only one permitted intermediate adit, at about midpoint along the 15kmlong alignment, influenced several aspects of decisionmaking on construction, not least the choice to build the pilot.

The 1.5kmlong adit with a grade of 12.9% (called an inclined shaft in China) was advanced from a point between the two separate parts of the environmental nature reserve and into a suspected karstic zone of limestone. As anticipated, it connected with a large karstic network with a huge volume of water. The flow is being directed into an underground sump to be used for both firefighting and maintenance purposes during the operational life of the long expressway tunnel.

With the long drive to reach the only intermediate adit, a tunnel boring machine (TBM) had to be used for most of the pilot excavation. The distance would not support adequate ventilation for drill & blast excavation, although the tunnelling method was used from the opposite portal and was expected to complete approximately 5km of the pilot tunnel; the TBM would complete the other 10km.

An open gripper TBM was selected to bore the majority of the pilot tunnel to allow for observation of the geology as encountered rather than being closed off by a shielded TBM and precast concrete segmental lining.

PILOT TUNNEL

Next, the project managers had to decide where to locate the pilot tunnel and how to justify its added cost. In addition to enabling more investigation of the geological conditions, the pilot would further assist construction of the main highway tubes by:

- Providing space for laterally drilling pre-excavation grouting (PEG) and drainage arrays into the alignment of the main tubes;

- Supporting the ventilation needs during drill & blast advance of sections of the main tubes (these, and cross passages, are also excavated by the method);

- Reducing the vibration impact in low strength and fractured rock;

- Shortening excavation of the main tubes by providing access points to open additional drill & blast faces and mucking out routes; and,

- Providing additional access points for advancing the final waterproofing and in-situ concrete lining processes of both the pilot and the main expressway tubes.

In addition to these in-construction benefits, the pilot would have to have a purpose for the twin highway tunnel in operation. This came to mind readily for the project managers: the pilot would run between the two main tubes at an elevation slightly lower than their invert levels, and serve subsequent highway operations as:

- A central drainage facility;

- A facility for emergency ventilation purposes;

- A refuge for people in the event of an in-tunnel accident;

- An access route for emergency and maintenance vehicles; and,

- A bypass to isolate sections of the highway tubes for maintenance operations.

To meet all the above requirements, the TBMbored pilot would need to be large enough to accommodate a two-lane roadway and connect laterally to the main tubes via the project’s 36 smaller cross-passages for people and the 16 vehicle crosspassages.

With these decisions made, the contractor engaged to complete the TBM pilot tunnel, one of four contractors engaged on the full tunnel project, selected an 8m-diameter refurbished gripper machine. The TBM was assembled on a limited laydown apron at the launch portal, its components having made a difficult journey to site on purpose-built tracks and through the snow and rain of a winter season. After 30 days in assembly, the machine was launched in October 2020, commencing its drive at the face of a 110m-long drill & blast starter tunnel.

ADVANCING KNOWLEDGE

The application of a TBM to an expressway tunnel project will fill a gap for the industry. There is a network of 200,000km of expressway in China, with 26,000km of that running through 25,000 tunnels, most of these, other than those under rivers, excavated as open-face, NATM-type, drill & blast constructions.

TBMs have been used on several long railway tunnels in China but application for express highway tunnels through mountains is something new. The experience of a TBM pilot tunnel of the Daliangshan No 1 Highway Tunnel project has proven the many benefits of such an investment.

During pilot excavation, however, the same geological risks had to be anticipated, including high volume water ingress, squeezing ground, karstic voids, and fault zones of poor ground conditions.

As a priority project, many research studies were supported on the TBM pilot tunnel including:

- Seismic predictions of geological features ahead of the face;

- Design of support parameters for different rock classifications;

- Support in soft rock with arches and straps;

- Forepoling in soft rock;

- Support using shotcrete and bolts in combination;

- Muck analysis and use as a valuable resource rather than a waste product;

- Design of gauge cutters to compensate for convergence;

- Scanning of supported headings to check deformation, and to check the same through the secondary lining once installed; and,

- Application of robots for installing arches as part of a national research project to reduce labour on tunnelling projects and increase safety.

As a benchmark in expressway tunnelling, the pilot tunnel has given rise to: 50 academic papers; development of 10 new technologies; formed the basis of 10 new codes of practice; and, 30 new patent applications have been filed. Other expressway projects in Sichuan, and in China, will make use of the lessons learned on this pilot project.

Participating in the important research project, the China Railway Academy (CRA) of Chengdu, Sichuan, was engaged to carry out specific studies associated with the TBM pilot drive. These included:

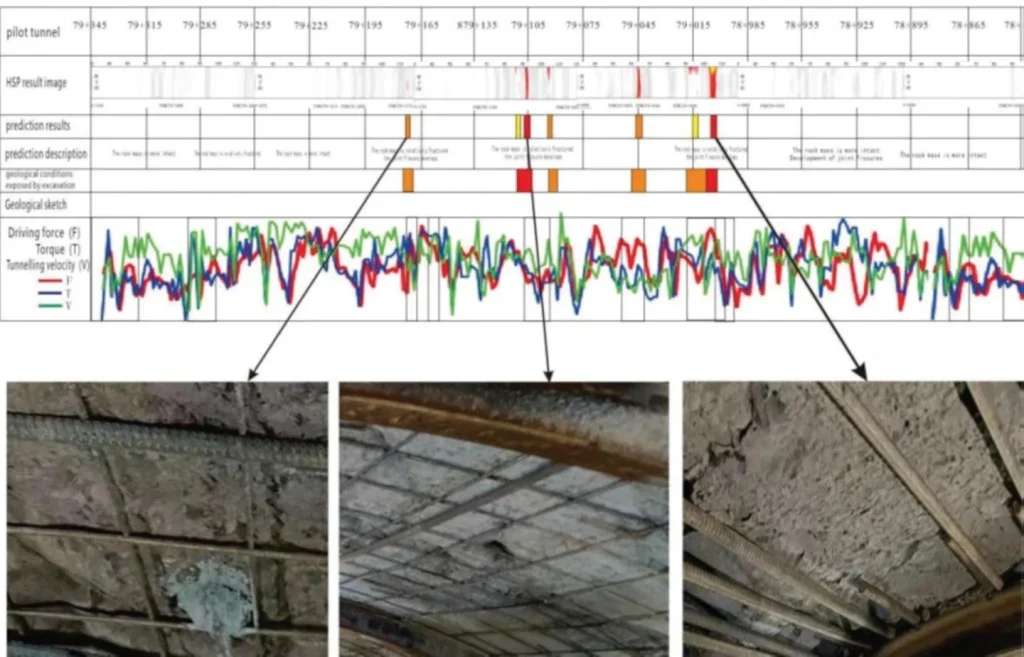

- Application of the CRA HSP Geological Prediction Systems to help predict conditions ahead of the face without stopping the TBM;

- Confirming rock class definitions and their support requirements;

- Study of the ventilation benefits of the pilot tunnel both during excavation of the two main tubes and in operation of the expressway tunnel once opened; and,

- Advance the study of construction cost unit prices.

For predicting conditions ahead of the face, CRA used its HSP217T on-board prediction system that uses the vibration of the TBM cutterhead, as it cuts the rock, as the excitation source. These vibrations are detected in rebound by the geophones installed in the rock of the tunnel wall behind the TBM; they help researchers to analyse the stratum reflection energy spectrogram and velocity distribution, which enables prediction and mapping of geological hazards in front of the face up to 120m in hard rock, and 100m in soft rock.

EXCAVATION

As the TBM advanced, use of the HSP217T horizontal seismic prediction system was found to give high accuracy in predicting the major geological features as encountered. As it happened, the greater issues were in the karstic limestone and fractured basalt, and less so in the mudstone which was expected to present squeezing behaviour but proved favourable for soft-rock TBM excavation.

The TBM bore went well, better than expected, and continued further than originally planned – driving an extra 2km when the planned 5km-long drill & blast advance from the opposite portal hit bad ground and came to a stop after 3km.

Reaching best advance rates of 49.12m/day and 723m/month, the TBM completed its 12km-long drive in 36 months, in September 2023. Excavation support was provided systematically with steel ribs on 900mm centres and primary shotcrete.

Constructing a pilot tunnel ahead of the main tubes however, and supporting groundwater drainage, didn’t eliminate the need for PEG. Control of water inflow was required on the project for environmental reasons to sustain the nature reserve on the surface, as well as to improve conditions for the excavation process and ensure the long-term durability of the structure in its design life. As it happened, the TBM drive, and the main drill & blast advances for the main tubes, encountered two identified fault zones in which estimated water inflow rates were significant.

During the site visit in May 2024, just a total of 5.2km of the main tubes remained to be excavated by drill & blast (approximately 2.6km in each tube), with excavation in both directions from a cross passage being used for vehicle access and mucking out through the pilot tunnel.

At the same time, several final lining operations were advancing, leading with gantries used to install the waterproofing membranes in the main tubes and the pilot tunnel, and also formwork shutters for in-situ concrete, and also advancing the reinforced final lining in all three tubes.

LOOKING AHEAD

As an auxiliary construction support drive, the pilot tunnel is finished with a transverse ventilation ceiling; in the event of a fire emergency in the main tunnels, smoke will be drawn into the ventilation ceiling duct of the pilot tunnel while the longitudinal ventilation fans in the main traffic tubes will keep the main tunnels fed with fresh air.

In another effort to maximise the value and return of the pilot tunnel investment, the Lexi Expressway Company is working with the regional electricity provider to negotiate a deal to carry high voltage cables through the tunnel rather than constructing pylons across the inaccessible terrain of the Daliangshan mountains. Wind farms for electricity generation are being actively developed in the region.

Upon completion of the Daliangshan No 1 tunnel, the future of the design will be examined.

“Maybe next time, we will have three TBMs – pilot and two main tubes,” said Director Lan. Through our interpreter, he explained: “The problem is, however, that a TBM profile to accommodate three traffic lanes would have to be about 13m in diameter with an excavated area of 132m2, while a drill & blast profile at about 12.5m-wide has an area of 105m2 and that, other than having a utility conduit in the invert, the lower part of the circular profile must be back-filled to create the road deck. This appears to be a waste, but this experience and others prove that TBM excavation is four times faster than drill & blast,” he added.

“So, while this is a first experience with the design of a central pilot tunnel for an express highway the experience has been positive and will be applied again,” he said. “There are three new long express highway tunnel projects in planning in Sichuan and the method has been adopted for one of them and is being considered for the other two, and more.”

Given the Daliangshan No 1 tunnel experience, the adoption of separate pilot drives and the introduction of TBM excavation to the field of express highway tunnel construction through the mountains has well and truly arrived.