Hundreds of drill and blast tunnelling projects, large and small, are underway each year across the world. Adits built, cross points and junctions opened up to run multiple advances, then main tunnels are progressed. Caverns are also created, with arch roofs, headings and benches.

The method is flexible, adaptable and a variety of jumbos, ground support and mucking loaders are brought to multiple projects.

Here, we sample but a few of the recent works, in some areas, well aware that so much more is happening – which we are always pleased to hear about.

GERMANY

Hydropower Plant conversion Contractor

Porr recently completed a key section of the access tunnel for the Rudolf Fettweis hydropower plant conversion, in Germany.

Porr is carrying out the construction works for the conversion of the run-of-river power plant to a pumped storage power plant. Excavation was completed for the portion of access tunnel that passes under Highway 462.

After passing beneath the road, the tunnel divides into the access tunnel and the discharge tunnel.

Porr says half the excavation work in the direction of the power station cavern has been completed from the intersection of the Schutter tunnel, secondary and access tunnels.

Excavation work is being carried out in the secondary tunnel towards the water storage cavern and in the energy discharge tunnel.

The total excavated length of the project is around 5.3km, of which around 4.7km is tunnels.

The power plant cavern is approximately 123m long, 20m wide and 42m high. In total, around 400,000m3 is being excavated, of which 200,000m3 is intended for water storage in the main and secondary tunnels.

Construction works started in Q3-’23 and the major underground hydropower conversion project is due to be completed in 2027.

The heritage-protected run-of-river power plant in Forbach was commissioned in 1914 and converting it to a pumped storage power plant will significantly increase its efficiency.

Porr is responsible for the of construction of mined caverns, water reservoirs and tunnels, the shell of the power plant cavern, construction of two pressure shafts, and foundation engineering work.

NORWAY

Stad Ship Tunnel

Norway is planning an uncommon very large tunnel – for ships, on a vital part of the country’s rugged fjord coastline.

The Stad Ship Tunnel project is being developed by the Norwegian Coastal Administration (NCA). The project development for the ship tunnel has been underway for the last few years.

Recently, the authority boosted its project organisation by establishing a collaboration with Statens Vegvesen (the Norwegian Public Roads Administration, NPRA) to help take forward project development.

While tunnels are uncommon for the coastal authority they are almost the bread and butter of the roads authority, which builds many inland and at various parts of the long coastline – including subsea road tunnels. In fact, the world’s longest subsea road tunnel project – Rogfast – is currently being constructed by NPRA.

The long twin tubes of Rogfast are being excavated by drill and blast method.

The ship tunnel will be shorter but still long – and be very high and wide, big enough for a ship to slowly move through, bypassing rough waters near a headland by going through the mountain instead of around.

NCA director-general Einar Vik Arset said: “The NCA is considered a one-time constructor when it comes to such a large project as the Stad Ship Tunnel, so it is not ideal to build a large internal project organisation; that is why we have initiated a collaboration.”

Several new resources are being brought in, including project and construction management, geology, tunnel operations, health and safety, and workplace regulations, to prepare the project organisation for the start of construction.

UK

Coire Glas hydro project

Exploratory tunnelling was recently completed for development of SSE Renewables’ 1.3GW Coire Glas pumped storage hydropower project, located at Loch Lochy in the Great Glen, in Scotland.

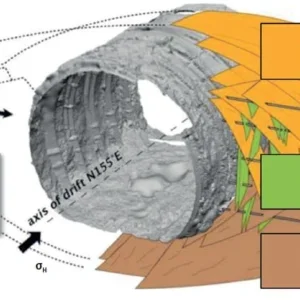

Strabag UK completed the 1.2km-long exploratory tunnel in the Scottish Highlands after beginning exploratory works in December 2022. SSE’s technical partners, Stantec and Cowi, designed and supervised the ground investigation programme.

The works included building a tunnel approximately 5m high x 4.5m wide through the hillside around the proposed location of the underground powerhouse caverns complex. The tunnel will allow the project team to gather accurate information on the geological conditions to inform the detailed design for the main works.

Exploratory drilling and testing will continue to further investigate the ground in the area of the proposed powerhouse caverns.

The Coire Glas pumped storage project would create 30GWh of long duration energy storage. With a greenlight on a final investment decision, main construction could start in H2-2026.

MUMBAI MAIN TUBES START SOON

Tunnelling has progressed on inclined adit construction for the Mumbai-Ahmedabad Bullet Train Project, paving the way for main construction work on the 21km-long tunnel between Bandra Kurla Complex (BKC) and Shilphata in Maharashtra. Adit excavation began at the end of 2023. Main construction will involve both NATM and TBMs