Itinera’s presence in Sweden has grown significantly with the Italian construction company securing two major subway projects simultaneously in in the capital, Stockholm. One of the projects is the Hammarby Kanal subway station lot with a 1.2km-long service tunnel and also a track tunnel of the same length.

In planning, the challenge was either to acquire expensive equipment for tunnelling or another solution – in this case opting for an equipment rental and services package. Leveraging Sandvik’s expertise, Itinera has been able to overcome the capital constraints associated with purchasing equipment outright.

The partnership for Hammarby Kanal shows collaboration can deliver significant results in challenging construction projects, with Itinera using Sandvik’s reliable machinery, on-site technicians, and comprehensive support to support smooth operations and to enable downtime to be minimised.

Several factors led Itinera to collaborate with Sandvik, including prior experiences together and rapid deployability of the equipment on the tunnel project in Stockholm – crucial for meeting project timelines.

Frida Hesselgren, Project Manager at Itinera, says: “Many of us working on the project have previously collaborated with Sandvik as a supplier with good results, making it an easy decision.”

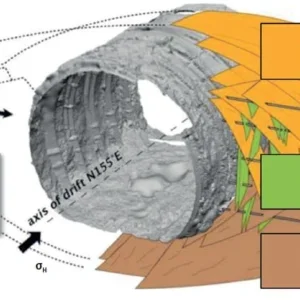

Itinera, in previous projects, had primarily used tunnel boring machines (TBMs) for excavation, but the Hammarby Kanal project presented challenges, such as how to create the particular tunnel alignments and do so in Stockholm’s exceptionally hard granite. As a result of these specific requirements – local geological plus the length and incline of the tunnels – the needs of the project called for the drill and blast method to be employed.

This type of project is also challenging due to the urban location, working in and under a major city. The working space is narrow and being cautious with noise, vibrations etc. is an absolute requirement. For Itinera, it has been helped to work with a company familiar with the local conditions.

Underground, despite the somewhat diverse nature of the rock quality encountered, so far Itinera has experienced minimal difficulties from equipment failing and production stoppages. Sandvik’s machines have performed reliably to ensure uninterrupted progress with the project’s time-critical nature.

Gustaf Marelius, Block Manager, Rock at Itinera, says: “We can’t afford to stand still; any production stoppages are out of the question. Time is the most valuable asset we have here.”

Itinera’s rental agreement with Sandvik includes a fleet of machines that comprises – in total for the two tunnel projects: four DT1132i 3-boom rigs, with one dedicated to long-hole stope handling for injection drilling; three DT923i 2-boom rigs; and, a Commando DC300Ri surface rig for smaller tasks. The selection of these machines was to ensure maximum capacity within the limited workspace available.

The agreement also includes the Sandvik Rod Handler system (SRH) for automated grouting, and the iSURE® (Intelligent Sandvik Underground Rock Excavation) software, designed specifically for optimising drilling and blasting cycles through the generation of comprehensive data.

Erik Lundén, Measurement Engineer at Itinera, says: “I use iSURE® daily as I create all the drilling plans and transfer them to the drilling rig.”

Under the agreement, proactive support on-site includes a spare parts inventory – rods, bits, and casings, among other RD535 30kW drifters, Sandvik Alpha 360 Rock Tools, and GT38 rods – to help minimise downtime. Sandvik’s technicians, working alongside Itinera’s team, can then promptly address any equipment issues, preventing significant stoppages and keeping the project on track.

Mathias Stubbans, Workshop Manager at Itinera, says: “We have a good dialogue with Sandvik’s service technicians; we have follow-up meetings every week.”

Consolidating the supply of drilling rigs, rods, and steel has enabled Itinera to benefit from streamlined communication and ease of management. With everything centralised through the all-inclusive approach with Sandvik, any issues arising can be promptly addressed. The consequent simplicity and efficiency lets Itinera focus on its core competencies, while Sandvik’s technicians work on-site full-time, closely collaborating.

It is felt this integrated approach facilitates seamless communication, and so strengthens relationships and enables effective problem-solving. Regular follow-up meetings enhance dialogue and enable both teams to address concerns promptly.

Sven Kvick, Operator at Itinera, says: “I like the simplicity; there aren’t many concerns.”

This rental approach, combined with a comprehensive parts and service agreement, proved to be the most advantageous option for Itinera, allowing for accurate forecast of costs and helping to eliminate uncertainties associated with depreciation of purchased equipment. At the completion of the project, Itinera returns the rented machines to Sandvik. They will be available for future projects.