Across the world, tunnel boring machines are busy making successful headway on projects with lengths long or short, and utilising diameters large or small. Full view of the TBMs at work is possible at key milestone stages, such as assembly, lift, launch, breakthroughs and completions or pull-throughs or turns, and then eventual dismantling, at least in the cases of the largest of the machines.

The TBMs vary in design, as do their back-up trains of varying lengths and the optimised logistical support for spoil removal and materials supply.

Much can be said but seeing also says so much. In the following pages, we spotlight a number of TBMs active on projects and at highly visible junctures in their challenging tunnel boring activities.

The machines are supplied to the jobs and customers by some leading manufacturers, such as China Railway Construction Heavy Industry Corporation Ltd (CRCHI), Herrenknecht, China Railway Engineering Equipment Group (CREG), and Terratec. The images comes from projects underway in China, Chile, Peru, Austria, Italy, France, India and Thailand.

There are far more machines in more places right now across the globe but the sights to see here offer an opportunity to capture key moments among them, as they pass so quickly. Tunnelling forever moves on.

A TASTE OF EUROPE

While Herrenknecht machines are working across the world, this selection spotlights some in Europe, where two TBMs are ready for works in very different parts of the Alps while another is underground again in the capital of France, which is about to host the 2024 Summer Olympic Games.

Alps: Brenner Base Tunnel

Earlier this year, Herrenknecht presented its eighth TBM to work on the Brenner Base Tunnel (BBT), which is a high-speed rail tunnel project under the border of Austria and Italy. It is a key link in one of the rail corridors in Europe’s strategic initiative to expand the high-speed transport network. The initiative is Trans-European Transport Network (TEN-T).

The double shield TBM was also the second of the two identical machines it is supplying for Brenner’s Lot H53, which is being constructed by contractors Porr and Marti, working together as ARGE H53 BBT. They will bore parallel tunnels on this Austrian section of the twin-tube rail link deep under the Alps.

The US$1bn Lot H53 is the largest construction package in Austrian history.

For the excavation, the double shields are 10.37m-diameter, 183m long and weigh around 2,700 tonnes.

The most recently presented TBM – ‘Olga’ – is to build the East Tunnel towards Innsbruck on the Pfons-Brenner portion of the project. Its sister machine – ‘Wilma’ – was presented in March and will dig the West Tunnel.

Tunnel boring is scheduled to start in shortly.

The Brenner Base Tunnel project is 64km-long and mostly underground, making it the longest rail tunnel in the world. The stations at each end of the link Innsbruck, in Austria, and Fortezza, in north Italy. As a key part of the TEN-T’s Scandinavian-Mediterranean Corridor, the Brenner the project will reduce rail travel time between the stations from 80 minutes to 25 minutes, or more than two-thirds, through the Brenner Pass.

Alps: Lyon-Turin

Tunnelling work on the Lyon-Turin Base Tunnel project has been pushing ahead on multiple fronts over the last few years, and gearing up are a number of TBM drives to help excavate Mount Cenis Base Tunnel, a key part of the high-speed underground rail line through the lower Alps.

Recently, two Herrenknecht machines headed for site after passing Factory Acceptance Tests (FAT).

One of the recent FATs was for a 10.4m-diameter TBM that is to excavate a 9km-long section of the north tube, parallel to the already completed south tube (previously bored by TBM ‘Frederica’), between Saint-Martin-La-Porte and La Praz.

The TBM will be operated by the Italian-French group CO 6-7, comprising Vinci Construction, Webuild, Dodin Campenon Bernard and Campenon Bernard Centre Est.

The other TBM supplied to CO 6-7 is to bore one of the two main running tubes between La Praz and Modane.

Each TBM has 8,100kW of power, weighs 2,300 tonnes and is equipped with 61 cutters.

The 57.5km-long Mont Cenis Base Tunnel straddles the Italian and French border with most of the alignment (45km) in France and the remainder (12.5km) in Italy. It will be one of the longest rail tunnels in the world. The project developer is Tunnel Euralpin Lyon-Turin (TELT). In total, the link is 65km-long in the border section, and is longer beyond that area, in each direction toward Lyon and Turin, respectively.

Paris: more TBM excavation

The last TBM that will be working on construction of Line 18 of the Grand Paris Express is about to get underway.

The 9m-diameter variable density machine is the third shield to work on Line 18 and also the 30th TBM so far to be performing bored excavation for the new 200km metro project in the French capital.

TBM ‘Awa’ is starting on its 6.7km-long tunnel drive at the future Guyancourt station, in western Paris, and will drive almost to Versailles-Chantiers station, where it is due to breakthrough at the end of 2026.

Weighing 122 tonnes, the TBM comprises reused components from TBM ‘Céline’ which built the 5.9kmlong tunnel between Palaiseau and Massy, over 2021- 2023, on the eastern section of Line 18.

TBM Awa is named after Awa Camara, president of the Guyancourt association, Second Breath, which supports parents of children with disabilities.

A consortium of Ferrovial and Spie Batignolles wase awarded the €428m Line 18 contract in April 2022. The line connects Orly Airport to Versailles-Chantiers.

The consortium has an agreement with energy utility EDF to ensure the electricity required during construction work will be entirely from renewable sources. The agreement provides for the supply of 25GWh, equivalent to the power used by a city of 85,000 people over three months. Of the total, slightly more than half, or 13.5GWh, will be used to drive the TBM and the balance will be used to operate the ancillary equipment required for construction. The deal will avoid the emission of 7,396 tonnes of CO2.

In addition, the excavated material, which will be mainly sand, is to be used in other phases of the project.

ADVANCING IN CHINA, CHILE

Among the many recent TBM excavations where CRCHI’s tunnelling machines have been engaged are large diameter projects in China, Chile and Peru – with slurry, earth pressure balance (EPB) and hard rock types, respectively, either preparing for or finished in action.

Ready for Shenzhen-Shenshan

A giant slurry TBM from CRCHI was recently manufactured for the Shenzhen-Shenshan railway project, in China.

The 14.33m-diameter TBM – named ‘Pingshandong No. 2’ – is 130m long and weighs 3,800 tonnes. It will be deployed on the SSSG-3 section of the Shenzhen- Shenshan Cooperation Zone Railway Station Project.

Principal excavation involves a single bored length of 4.6km to create a tunnel that runs parallel to the Xiamen- Shenzhen high-speed railway. The new tunnel will pass under a river and residential neighbourhoods.

Geology along the large diameter bored tunnel alignment comprises argillaceous sandstone, limestone, granite, and different parts of the route have karst and faults, respectively.

The slurry TBM is equipped with a composite cutterhead, telescopic main drive, double crushing system, high-efficiency material transport system, and box culvert fine-tuning device.

Launch in Santiago

An earth pressure balance (EPB) shield from CRCHI was recently launched as part of the major constructions works underway for Line 7 of the expanding metro network in Santiago, Chile.

The 9.8m-diameter EPB machine – named ‘Matukana’, symbolising brightness and hope – is 105m long, weighs 1400 tonnes and has an installed power of 5700kW. The TBM has a compound cutterhead equipped with 19” disc cutters.

Geology comprises sandy soil layers, limestone and other strata, and there are strict settlement control requirements for passing beneath densely populated residential areas.

Formation boulders will be a challenge in the geology along the alignment and the excavation plan is for cutting tools to be changed every 2km as the machine advances.

Santiago metro’s Line 7 is 26km-long with 19 stations. The TBM will be deployed on a 7.9km-long section, which is mostly underground and includes a 6.7km-long tunnel.

Hard rock hydro

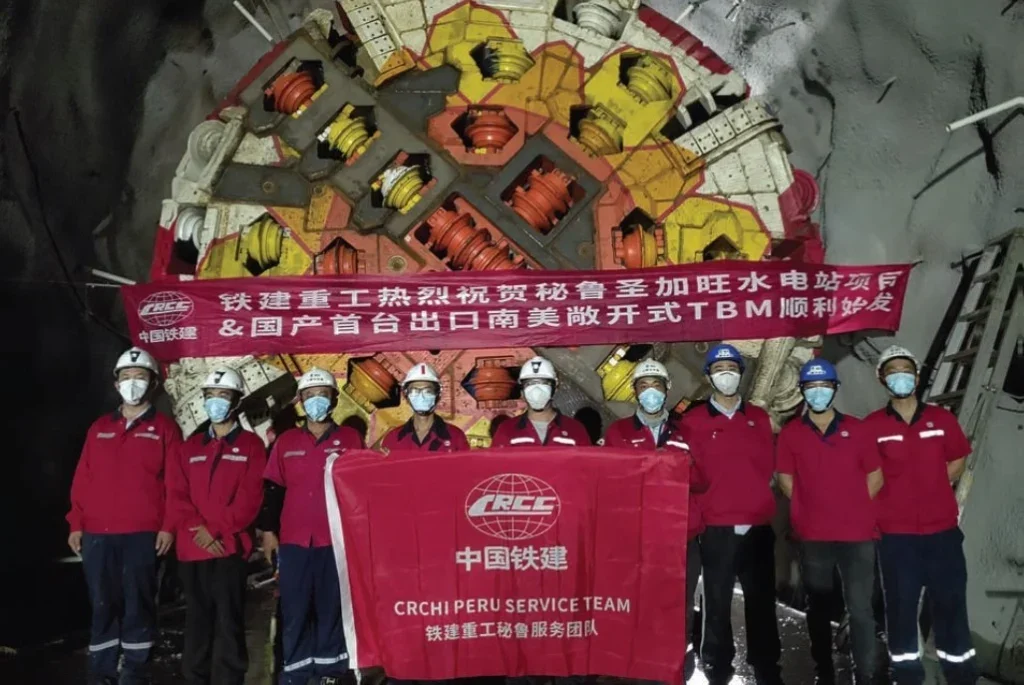

CRCHI’s first hard rock TBM in South America worked on the San Gawang hydropower project, in Peru, and achieved some significant advance rates, such as more than 1000m in a month.

The 209MW hydro project has Chinese investment as part of its Belt and Road Initiative, in South America. The project is the first power sector investment in Peru by Chinese enterprises, says CRCHI.

The TBM was 5.83m-diameter and geology was medium to high strength rock with good stability, the manufacturer says.

The high progress rate for the month came from increasingly higher single shift advance rates in late 2022, leading to progress doubling from 10m to 20m on shifts and then more – eventually to reach more than 26m. The maximum advance for the machine and crew in a day was 46m.

San Gawang hydro project is expected to support optimal allocation of regional water resources.

TRANSPORT FOCUS

With multiple TBMs in use around the world, serving different sectors and tunnelling challenges, we briefly spotlight the recent milestones with machines for two transport projects – in Italy and China, respectively.

EPBM ready for Sicily

Following its FAT earlier this year, a 9.48m-diameter explosion-proof EPB TBM is being shipped from China to Italy to work on Lot 4A of the Palermo-Catania rail project, in Sicily.

The EPBM – ‘CREC 1403’ – was manufactured in CREG’s factory in Tianjin and is approximately 251m long, weighs around 2300 tonnes and has a double-shell to help with disassembly in the tunnel.

The TBM features energy-saving technology, an invert cast-in-place system, and an intelligent maintenance system. The explosion-proof design meets ATEX and CE standards.

Lot 4A of the Palermo-Catania railway project consists of Montestretto, Salso and Trinacria tunnels. Geology is mainly clays, diatomite, diatomaceous marl, chalk, and chalky clay.

The lot is part of the Caltanissetta Xirbi to Nuova Enna section of the project. The contractor is a consortium of Webuild (leader) and its subsidiary Seli Overseas, and Ghella and its subsidiary TunnelPro.

The new Palermo-Catania-Messina axis is among Europe’s TEN-T projects along the Scandinavian- Mediterranean Corridor.

Rectangular pipejacking

CREG says that the world’s first hard rock rectangular pipejacking machine achieved breakthrough after full face excavation on a road project in Chongqing, China.

The machine – CREC 1112, developed and manufactured by CREG – is 10.42m-wide and 7.57m-high.

It is equipped with six circular cutterheads and six drum cutters, meaning the tunnel face is completely covered.

The TBM excavated the pipejacking section of N-Standard-Partition Street Interchange C-Traffic-Node A-Ramp project in the Chongqing Liangjiang New Area. The project links Lushan Avenue, near the North Square of Chongqing North Railway Station, and the Chongqing Inner Ring Expressway.

CREG says it is the first time a large cross-section rectangular pipejacking machine has completed fullface excavation, solving the problem of blind area excavation, especially in hard rock strata, by a noncircular TBM.

The manufacturer’s team also customised the machine’s settlement control and attitude control systems to provide stronger rock breaking capability and tunnelling performance, and minimise ground disturbance.

The tunnel passes under two, two-lane roads and over is shallow at 4m-5m. CREG equipped the machine with three intelligent systems for thrust control, soil conditioning, and friction reduction, respectively. Together, they controlled the cutterheads, shield articulation cylinders, and gave real-time adjustment of advance direction. They also provided dynamic monitoring of muck and friction reduction material coefficient.

The machine has a maximum monthly advance rate of about 30m, which CREG says approximately halves the construction time, saves 60% in labour cost compared with hand excavation, and it improves safety.

ASIA: CITY AND MOUNTAIN

Terratec has been supplying TBMs for multiple projects across Asia, including some in the same city – such as in Bangkok, Thailand – as well as for remote projects such as Vishnugad Pipalkoti hydro project, in India. Here we spotlight two recent FATs for machines set to bore on one project Bangkok, on the Purple Line of the city’s growing metro network, and also catch a glimpse of the TBM in the hydro tunnel, in India.

Thailand: Bangkok metro

Recently, Terratec presented a second new 6.39m-diameter EPB TBM (‘S114’) for tunnelling work on Bangkok metro’s Purple Line (C3).

The first EPBM (‘S113’) had its FAT at the end of 2023.

The two TBMs will bore a 3.12km-long tunnel on the Purple Line, in a section linking Phan Fa Station to Memorial Bridge Station and pass through two metro stations on the way.

Geology along the tunnel routes will include sand layers, such as soft clay, stiff clay, dense clayey and silty sand.

The alignment of the new metro line also passes through the historic area of the city, which includes landmarks such as the Grand Place and ancient temples.

The Purple Line will also pass beneath, and connect with, operational Blue Line tunnels at the Sam Yod interchange station.

On a 150m stretch, the TBMs will also bore under the Chao Phraya River.

To address these geological conditions, the EPBMs’ soft ground cutterheads are fitted with a flat spoke type with copy cutters.

The concrete segmental rings to be erected behind the TBMs are traditionally reinforced, 275mm-thick by 1400m-wide, Universal rings (5 + 1). Muck removal, segments, and the supply of consumables will be transported by rail and battery locos. Terratec TBMs are equipped with the Enzan laser guidance system, which provides remote monitoring of the entire tunnelling system.

The Purple Line will be approximately 23.6km-long, comprising a 14.3km-long underground section, a 9.3kmlong elevated section and 17 stations. It is the city’s fifth rapid transit line and construction started in Q3-2022 for metro train services to commence in 2027.

India: Vishnugad Pipalkoti

A 9.86m-diameter hard rock double shield TBM from Terratec is driving ahead on the Vishnugad Pipalkoti hydropower project, in Uttarakhand state, India. The manufacturer says it is the largest double shield working in the Indian Himalayan region.

Primary contractor on the hydro project is Hindustan Construction Co (HCC).

The scope of works on the 444MW run-of-river hydro project includes dams, water conveyance tunnels and range of underground structures – including diversion and intake tunnels, sedimentation chambers, the 13km-long low pressure headrace, a surge shafts and pressure shafts and penstocks, and a powerhouse complex housed across two caverns.

The TBM is boring the headrace tunnel and in January this year achieved a monthly progress rate of 431m. The cutterhead has 19” discs and a dozen large bucket openings. Terratec has supplied a continuously advancing conveyor to support the TBM, and an advancing tail piece with an active hydraulic system matches steer/roll of the machine.

Geology in the project area and headrace is dolomitic limestone and slate, respectively, with some fault, shear and thrust zones.