INTRODUCTION

Reliable access to water is the cornerstone of a growing and successful community. This much needed resource is afforded by the execution of major conveyance projects which are growing in number across North America.

When the subject of drought is broached, many people first think of the American West where there is long history of contention over available water. The reality is that many American communities, regardless of geographic location, are threatened by the adverse effects of drought, and must think proactively about solutions that add resiliency and dependability to their water infrastructure.

One of the best examples of a community rising to meet this challenge is the Red River Valley Water Supply Project (RRVWSP).

RRVWSP PROGRAMME PURPOSE

Central North Dakota and the Red River Valley are drought-prone regions with limited and unreliable surface water supplies that are inadequate during drought conditions.

In the 1930s, Fargo, North Dakota experienced zero flow in the Red River during a severe drought; models have shown that a similar magnitude drought would have an estimated financial impact of US$33 billion (2023$) over a ten-year period.

Supporting studies of the catchment show that a severe drought, like that of the 1930s, will likely reoccur in the region by 2050.

In addition to limited surface water supplies, limited groundwater supplies are nearly fully appropriated and North Dakota State law discourages the conversion of groundwater irrigation to drinking water.

The RRVWS project is necessary to protect North Dakota communities and economy from the devastating effects of drought. The emergency water supply to central and eastern North Dakota during times of water scarcity will protect public health, ensure ongoing economic vitality, and provide for environmental benefits in the river systems by augmenting the base flow of local rivers during periods of severe drought. With continued growth and industrial development, the RRVWSP is needed to mitigate against drought conditions that would cause costly water shortages, foster economic development by meeting municipal, industrial, and rural water demands, and promote environmental sustainability.

PROGRAMME ENTITIES

A project of this nature and size involves many entities to execute. As the key programme stakeholders, Garrison Diversion represents the state and Lake Agassiz Water Authority the multiple cities and local water districts in central and eastern North Dakota and Minnesota.

From an implementation standpoint, Black & Veatch Corporation (BVCI) and Advanced Engineering and Environmental Services, LLC (AE2S) have provided programme management, engineering design, and construction administration and inspection services for the multitude of project components. Several components of this programme require compliance with U.S. Army Corps of Engineers (USACE) permits, which has been coordinated between KLJ Engineering and the U.S. Fish & Wildlife Service (USFW) and the U.S. Department of the Interior, Bureau of Reclamation (Reclamation).

To construct these components, various general contracting, foundations, and trenchless construction firms such as Michels Trenchless, Garney Companies, Industrial Contract Services, Industrial Builders, and Minger Construction Companies have been instrumental.

PROGRAMME COMPONENTS

When in service, the greater programme will withdraw water from the Missouri River and convey it to the Main Pumping Station (MPS) and water treatment facility near Washburn, ND. Raw river water will be treated at the MPS site to meet water quality standards established by the North Dakota Department of Health/Department of Environmental Quality requirements. Treated water will be conveyed via an approximately 265.5km of 1830mm (165 miles of 72 inch) diameter, multi-county pipeline system before discharging into the Sheyenne River. Lake Ashtabula will serve as a regulating reservoir, allowing controlled releases of the water as needed.

To match the overall phasing and funding of the RRVWSP programme, the project has been divided into two elements: the Missouri River Intake System and the Pipeline System.

MISSOURI RIVER INTAKE SYSTEM

The Missouri River Intake (MRI) is located in central North Dakota, approximately five miles southeast of the city of Washburn, and consists of a conventional submerged intake structure, a conveyance tunnel, and the MRI Pump Station (MRIPS) wet well/shaft. The system is being constructed in a series of three contracts, as shown in Figure 2.

Contract 1 consisted of constructing a 12.8m (42ft) diameter by 19.8m (65ft) deep concrete wet well shaft, site and site access improvements and maintenance of access road, grading, clearing and grubbing, and drainage improvements. The contract was completed in Fall 2021 to facilitate access for Contract 2.

Contract 2 consisted of constructing the foundation and installation of piping in the Missouri River for the future submerged passive intake screen. This included the installation of approximately 487.7m (1600ft) of 72- inch diameter tunnel connecting the existing wet well/ shaft on the riverbank to the screen structure foundation in the river. Contract 2 also included installation of the final liner for the MRIPS wet well and was substantially completed in Spring 2023.

Contract 3 will include work associated with installing mechanical and electrical equipment that are required to make the Intake System operable near the end of the decade.

PIPELINE SEGMENTS

In order to convey water from the Intake System to the Discharge Structure at the Sheyenne River, a series of buried pipelines will be constructed under separate smaller segments as part of the RRVWSP programme.

Contract 5 constitutes approximately 45.1km (28 miles) of pipeline spanning from the intersection of 1st Street NE and 57th Avenue NE near Sykeston, ND in eastern Wells County and continues east approximately midway into Foster County to end near the intersection of 1st Street SE and 83rd Avenue SE near Kensal, ND. Contract 5 is further divided into the following contracts:

- Contract 5a: construction of ~2.0km (1.25 miles) of 72 inch diameter steel water pipeline, including one 96-inch diameter trenchless crossing under U.S. Highway 52/281 and the Red River Valley and Western Railroad.

- Contract 5b: construction of ~14.5km (9 miles) of 72-inch diameter steel water pipeline, including one 96-inch diameter trenchless crossing under the Canadian Pacific Railway.

- Contract 5c: construction of ~12.9km (8 miles) of 72-inch diameter steel water pipeline, including two 96-inch diameter trenchless creek/river crossings and one 96-inch diameter trenchless gas line crossing.

- Contract 5d: construction of ~16.1km (10 miles) of 72-inch diameter steel water pipeline, including two 96-inch diameter trenchless wetland crossings.

Contract 6 constitutes ~40.2km (25 miles) of 72- inch diameter steel pipeline spanning from east of Carrington, ND to southwest of Cooperstown, ND. Contract 6 consists of 12 trenchless crossings under several wetlands, creeks, highways, a BNSF railroad, and a gas pipeline.

This contract will be divided into two, 20.1km (12.5 miles) segments of 72-inch diameter steel pipeline: Contracts 6a and 6b.

Contract 7 constitutes ~20.9km (13 miles) of 72-inch diameter steel pipeline spanning from approximately 7 miles west of Cooperstown to approximately 5.6km (3.5 miles) east of Cooperstown, near the discharge structure at the Sheyenne River in Griggs County. Contract 7 is evaluating the design of 20 trenchless crossings of wetlands, creeks, roads, and railroads.

RRVWSP TRENCHLESS INSTALLATIONS

Across Contracts 5 through 7, 39 trenchless crossings spanning 2233m (7325 LF) have either been constructed, are actively being installed, or are in various stages of design as shown in Table 1. Trenchless installation facilitates the delivery of this pipeline while reducing disturbance of sensitive wetlands and creeks as well as preventing the interruption of service on highways, railroads, and utility lines.

TRENCHLESS BORING MACHINES

Trenchless solutions are employed to meet to the frequent challenge of constructing and installing linear conveyance infrastructure in ground conditions where traditional cut and cover methods are either not feasible or may be detrimental to sensitive environments. For the RRVWSP programme, construction in varying ground conditions was possible due to advancing technology in tunnel machine manufacturing – specifically, slurry Microtunnel Boring Machines (MTBM) and Earth Pressure Balance Machines (EPBM) were leveraged to execute this work.

MTBMs

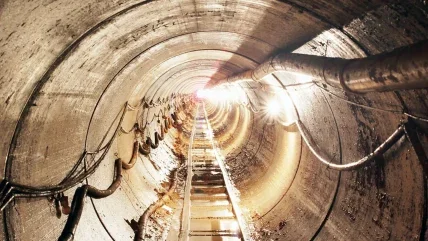

For Contract 2, a slurry MTBM was employed to directly install the conveyance tunnel from the wet well shaft to the intake structure in the river using a one-pass system. A jacking frame in the launch shaft (Figure 3) applies pressure to the casing pipe which advances the MTBM, which in turn advances the pipe alignment. Additional pipe segments are connected and jacked into place from the launch shaft as the MTBM progresses forward.

Slurry lines are also extended to facilitate continuous muck removal. A guidance system within the MTBM is employed to assist with installing pipe to required line and grade tolerances. This process continues until the MTBM reaches the reception shaft. Once the MTBM reaches the reception shaft, the MTBM is removed, and the process of making connections to existing structures can begin.

Slurry MTBMs are applicable to coarse-grained ground with high groundwater conditions, such as those anticipated in Contract 2.

EPBMs

For Contract 5a, an EPBM was employed to construct the trenchless crossing beneath the railroad and highway to minimise environmental impacts and disturbance to existing infrastructure (Figure 4). Like the MTBM, the EPBM also utilises a jacking frame to apply pressure to the pipe segments to advance the alignment as the machine excavates forward.

EPBMs are more suitable for fine-grained, or clayey ground, which can be conditioned to turn the excavated material into a fluid that balances the pressure at the face of excavation.

Without the need of a dedicated slurry separation plant, the construction footprint around the launch shaft is smaller.

DESIGN AND CONSTRUCTION PROCESS Intake System

Intake System Contracts 1 and 2 have been completed after detailed design and construction. The location and sizing of the Intake required detailed hydraulic modelling of the intake system as well as its impact on the Missouri River. As such, it is situated on an erosional bend in the river where water depth and velocity are advantageous, and the potential for sediment deposition and silting in of the structure is lower. This location is west of a USACE armored shoreline that regulates the main channel and prevents further erosion of the riverbank.

Due to in-water construction and presence of Threatened & Endangered (T&E) species, coordination among multiple agencies and firms was instrumental to ensure compliance with several USACE permits.

USACE NWP12 required monitoring and compliance measures for T&E species. Various monitoring periods between April to July and September to October required the MRI construction and 24/7 tunnelling schedule be developed to reduce the potential for T&E species-related work delays. Compliance measures included daily surveys for Piping Plover and Whooping Crane and suspension of work if spotted within the jobsite radius. In-water work was prohibited for Pallid Sturgeon in April to June and clearing and grubbing were prohibited from June to July for the Northern Long- Eared Bat.

Preferred construction means and methods were specified; 3 intermediate jacking stations (IJSs) were specified and installed to ensure adequate management of jacking forces during mining and any unanticipated stoppages. A top hat seal system was required at both launch and reception shafts, consisting of two seals and adjustable fingers to prevent groundwater and soil infiltration. To construct the intake, an MTBM was launched from the MRIPS wet well/shaft on land to install a 487.7m (1600 ft) long 72-inch ID Permalok steel pipeline. A temporary steel sheet pile cofferdam (Figure 5) was constructed in the Missouri River to serve as both the foundation for the MRI and a reception shaft for the MTBM. The conveyance tunnel was excavated in soft ground at a 0% slope and installed using a one-pass method with the jacking pipe serving as the carrier pipe connecting the MRI to the MRIPS.

Despite careful planning and coordination, this project encountered several challenges. Executing a schedule around T&E black-out periods led to a winter construction for the temporary access bridge and cofferdam. Sheet pile driving operations dealt with 50+ mph wind speeds, sub -40°F windchill temperatures, and 2ft-thick river ice. Split sheet pile interlocks and material migration into the cofferdam caused considerable time spent by divers welding steel plates over the gaps and re-excavation before placing the concrete plug.

Midway through the 24/7 mined tunnel drive, the launch portal seal was tearing. The repair, which completely replaced the launch window and rubber seal, halted mining operations for ~48 hours to ensure a total failure wouldn’t flood the tunnel or shaft. After 26 days of near 24/7 operations, the MTBM mined into a flooded cofferdam and was successfully retrieved.

CONTRACT 5A

Contract 5a has been completed through detailed design and construction. This contract consisted of a single trenchless crossing installed under U.S. Highway 52/281, the Red River Valley and Western Railroad, and several buried utilities as part of the 2.0km (1.25 miles) pipeline segment (Figure 6).

The crossing was 131.1m (430 ft) long and installed in a two-pass method using a 2440mm (96 inch) diameter carrier pipe at -1.00% slope through glacial till containing elastic silts, sandy lean clays, cobbles, and boulders. Given the presence of a variable high groundwater table, preferred means and methods for microtunnelling and construction of launch and reception shafts were presented within the Contract Documents; shaft support methods included: steel ribs with gasketed liner plates, secant piles, slurry walls, or interlocking sheet piles with bracing.

Minger proposed using an engineered slide rail system as temporary excavation support for the launching and reception shafts in lieu of those listed in the Contract Documents, which was approved and used to support excavation.

An EPBM machine was used to advance the 96-inch carrier pipe tunnel through silts and clays with a high potential to clog excavation equipment. While the machine was effective in mining through silts and clays, some difficulties were experienced when boulders with frequency and parameters beyond those described in the Contract Documents were encountered during tunnel construction. Boulders and cobbles are obstructions to forward progress during tunnelling, which result in slowed advancement rates and differential cutterhead wear. After some alterations to advancement rate and face pressure, the first pass of the tunnel was complete, and the 72-inch diameter steel pipeline was installed within it.

Additional challenges on Contract 5a included careful monitoring and control of groundwater and settlement to ensure the existing railroad and utilities were minimally impacted by trenchless work. Minger used automated, real-time settlement monitoring instrumentation to ensure instantaneous notification of undue settlement.

CONCLUSION

At present, Contracts 5b, 5c, and 5d are under construction. Contracts 6a, 6b, and 7 are currently in various stages of detailed design and will be bid and awarded accordingly. Missouri River Intake Contract 3 is still in the preliminary design stage and will proceed forward in tandem with the completion of the pipeline contracts.

The RRVWSP has been a monumental coordination effort between many federal, state, and local entities to protect these communities and economy from the devastating effects of drought. The challenge of conveying water across the state is a daunting one, however leveraging trenchless installation methods has helped to bring the state one step closer to implementing its programme to protect the state’s future.