The M11 line of the Istanbul Metro traverses a region where underground water in the soil makes it impossible to construct cross-passages that can be used as escape tunnels.

Instead, the M11 uses a high-pressure water mist system from SEM-SAFE Fire Safety A/S, Fully owned by Siemens. By quickly suppressing fires using water mist, the system ensures passenger safety in the absence of escape tunnels. It was the world’s first water mist system to be installed in a metro.

Safe and efficient fire suppression

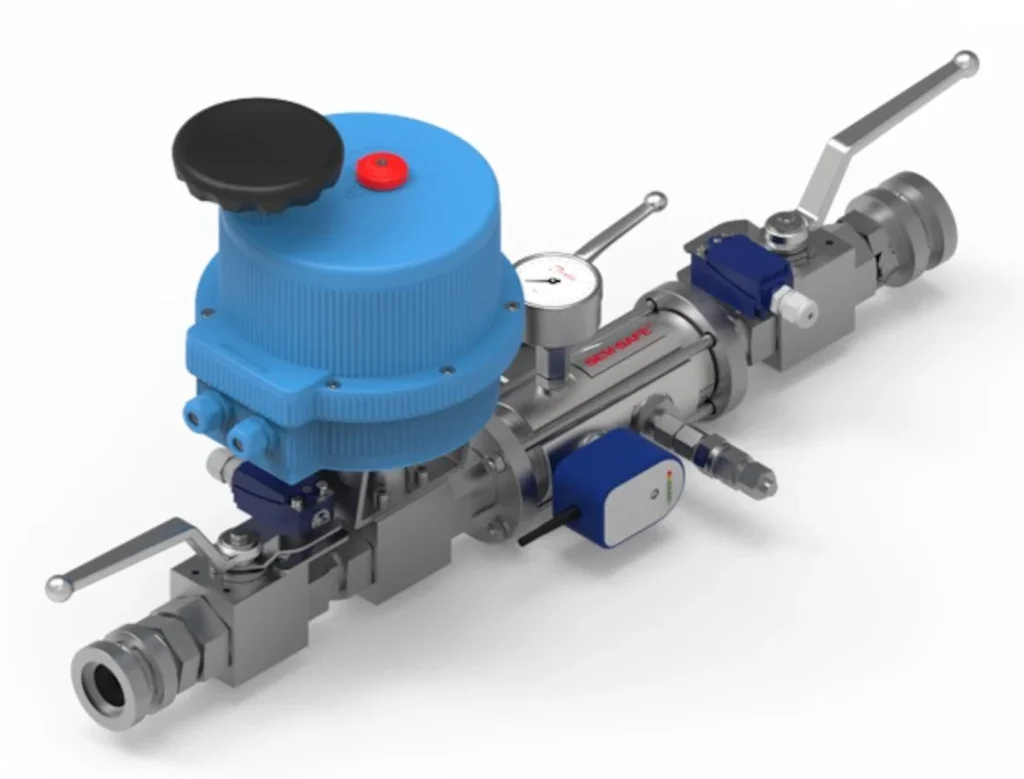

In the event of a fire, the pumps of the high-pressure water mist system rapidly provide water for the affected areas through section valves. The water is forced through nozzles at high pressure to create a fine mist that simultaneously lowers the temperature and removes oxygen, suppressing the fire. The water mist is completely harmless to staff and passengers on the metro.

To ensure efficient fire protection and prevent the fire from propagating quickly, the system is activated in the affected zone plus the adjacent zone.

Serving one of Europe’s busiest airports

Since opening in 2019, Istanbul Airport has evolved into one of Europe’s busiest airports, serving almost 80 million passengers in 2024. Efficient public transportation is therefore very important, and the M11 line, which opened in 2023, connects the airport with central Istanbul and has a capacity of 800,000 travellers daily.

The SEM-SAFE® solution on the M11 line covers two tunnel segments with two tubes each. The first segment is 3,083 metres long and has 3,150 open nozzles connected by 4-inch water pipes divided into sections using 150 section valves. The second segment features 1,596 nozzles and 76 section valves.

Other benefits for metro systems

In addition to efficient fire suppression, the SEM-SAFE® system provides other benefits in metro tunnels:

- Whereas a sprinkler system usually requires the use of 10 or 12-inch pipes, the compact SEM-SAFE® system uses 4-inch pipes while delivering the required hydraulic performance.

- The system uses very little water compared to sprinklers. This reduces the volume of water in the tunnels, making evacuation easier and reducing the need for drainage, and the smaller water tanks reduce installation footprint and cost.

- Since the small pipes can transport pressurised water over long distances, a SEM-SAFE® high-pressure water mist system does not require several pumping stations. On the M11 line, one high-pressure pump unit for each tunnel segment was enough.

System test in Norway

On the M11 project, SEM-SAFE Fire Safety A/S had several meetings with the customer on how to ensure adequate protection in the absence of escape shafts or tunnels. Guided by design criteria developed by consultants and the Turkish ministry of transport and infrastructure, SEM-SAFE Fire Safety proposed a solution and carried out a live test in Norway.

The test was witnessed by external fire system consultants RISE and the client, contractors, and the ministry. Based on the successful test, SEM-SAFE Fire Safety designed and delivered the solution for the M11.