As T&TI goes to press, Herrenknecht’s 15.2m diameter Mega TBM, the world’s largest operating TBM, should be joined by a second mammoth 15.2m diameter TBM to be used on Madrid’s M-30 south bypass project in Spain.

This second EPB machine, manufactured instead by MHI-Duro Felguera will be used by the FCC and Dragados JV to bore the 3.65km long south tunnel for the scheme. On 21 February, Madrid’s mayor, Alberto Ruiz Gallardón, visited the site with representatives of the project’s promoters, Madrid Calle 30, to view progress on the machine assembly, prior to commissioning in March.

Mitsubishi Heavy Industries (MHI) and Duro Felguera formed MHI-Duro Felguera in 2003 to carry out “engineering, design and manufacture of tunnel boring machines for both the Spanish market and other European countries, North of Africa and Latin America”. In this instance, the cutterhead was designed by MHI and the back-up by Felguera Construcciones Mecánicas. The TBM is planned to have an average daily advance of 20m per day, with a minimum monthly progress figure of 360m.

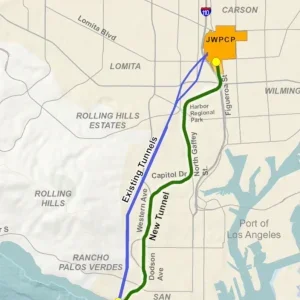

Herrenknecht’s machine is being operated by Necso and Ferrovial Agroman in JV to build the 3.65km long north tunnel on the M-30 scheme. Launched in November last year, it has the distinction of being the first machine in this size class. T&TI was told that by its 12th week of operation, it had already excavated 1,260m of tunnel, which equates to 630 rings.

Herrenknecht described how it has used two cutting wheels, arranged concentrically, on the head of its Mega TBM to gradually introduce the machine’s (up to) 125,268kNm of torque into the ground. An inner, 7m diameter, cutting wheel is mounted within the ring formed by the 15.2m diameter outer wheel. The inner and outer wheels can be rotated either clockwise or anticlockwise independently of each other. Two screw conveyors transfer excavated material from the bottom of the chamber that has been cut by the outer wheel. A smaller screw conveyor removes muck excavated by the inner cutting wheel.

The M-30 project aims to re-route the ringroad underground via twin tunnels, each carrying three lanes of traffic. The project has a capital cost of US$4.86bn, being let as a public private partnership (PPP) between Madrid city council (80%) and ACS/ Ferrovial (20%). British consultant, Scott Wilson, is providing support to the project, including reviewing the construction project, the financial model and payment mechanism and construction monitoring.